Here at Sentry Air Systems, filter efficiency testing is engraved in our DNA.

Air cleaners can have fancy widgets and be constructed from the sturdiest materials, but if their filters are inadequate then the product fails to live up to its name.

Our overarching mission, to provide clean air solutions to customers, is the reason why Sentry Air commits so much time and effort to filter efficiency testing.

While we have a growing list of in-house industrial hygiene reports, we always encourage customers to conduct their own efficiency tests; not only for added peace of mind but we love the data!

We recently received customer testing data of our Model 200 Winged Sentry for an isoflurane vapor application.

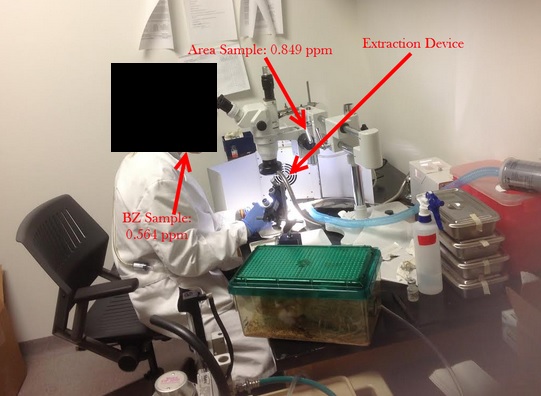

The customer is a safety engineer who assists medical researchers using isoflurane as an anesthetic agent on laboratory rodents prior to surgery.

The customer collected air samples near the researcher’s breathing zone and the immediate area both before using the air cleaner and again while the air cleaner was in use.

As the table below shows, the isoflurane concentration in the air reduced significantly once the air cleaner was turned on.

| Sample Location | Isoflurane concentration before air cleaner was used

(parts per million) |

Isoflurane concentration after air cleaner was turned on

(parts per million) |

| Researcher’s breathing zone | 3.6 ppm | 0.564 ppm |

| Immediate area | 6.3 ppm | 0.849 ppm |

While OSHA does not have a PEL for isoflurane, the CDC/NIOSH indicates it has the potential to cause reproductive abnormalities, DNA damage, and degenerative changes in the brain at very low concentrations.

The magnitude of concentration reduction experienced by the customer and noted in the table above, are particularly meaningful to those who use isoflurane in their work.

The customer reported that the “sampling conducted in this room showed significant improvements in the breathing zone and immediate surgical area. The results were a fraction of the action limit, indicating substantial, sufficient improvement.”

Sentry Air Systems conducted similar testing back in 2010. Results from that test indicated a 99.95% efficiency in the capture of isoflurane vapor when comparing concentration levels on the unit’s inlet and outlet. The entire 2010 report can be found on our website.

In an earlier blog post we discussed this specific application of isoflurane and recommended our Model 200 Winged Sentry (as used in customer testimonial) and Model 200 Floor Sentry as popular source capture options for this application.

If you would like more information about chemical fume control and source capture air cleaners, give Sentry Air a call at 800.799.4609, email sales@sentryair.com, visit our website or fill out the feedback form below.

Made in the USA

Made in the USA