ESD Safe

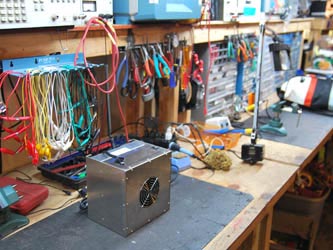

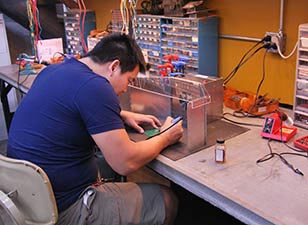

The ESD-Safe solder fume extraction unit is constructed for stationary, benchtop, and portable soldering applications that require the capture and filtration of airborne contaminants at the work surface level. This stainless steel solder sentry offers an effective, quiet & economical solution for many soldering operations which require ESD-safe fume extraction. This system is equipped with an energy-efficient fan and high-quality filtration media: typically HEPA or ASHRAE filtration. These filters are unique in that the primary materials have been constructed from fire-retardant products. HEPA filtration is up to 99.97% efficient on particles 0.3 microns and larger, while ASHRAE filtration is up to 95% on particles 0.5 microns and larger.

Benchtop Sentry

Model # SS-XXX-XXX

Unit Configurations Quick Compare

Features and Benefits

- ESD-Safe Base Unit & Anti-Static Flex Hose

- Highly Portable and Lightweight

- Reliable, Low Maintenance Operation

- Quiet Operation

- Simple, Quick "No Tool" Filter Change

- Long Filter Life

- Sturdy Construction

- Attractive Appearance

- Optional Velometer

Available Filters

-

HEPA FilterUp to 99.97% efficient on particles down to 0.3 microns

-

ASHRAE FilterUp to 95% efficient on particles down to 0.5 microns

Benchtop Sentry

Product Video

Cabinet Dimensions:

6.25"L x 8"W x 8"H

Weight:

8 lbs

Cabinet Materials:

18 ga. stainless steel

Motor:

Fractional Horsepower

Air Volume:

Up to 70 CFM

Electrical:

115/1/60, .46 amps

Sound Level:

Approx. 66 dba @ 3' from inlet

Patented Design:

U.S. PATENT #5,843,197

Product Video

Cabinet Dimensions:

6.25"L x 8"W x 8"H

Weight:

8 lbs

Cabinet Materials:

18 ga. stainless steel

Motor:

Fractional Horsepower

Air Volume:

Up to 70 CFM

Electrical:

115/1/60, .46 amps

Sound Level:

Approx. 66 dba @ 3' from inlet

Patented Design:

U.S. PATENT #5,843,197

Product Video

Cabinet Dimensions:

8"L x 8"W x 8.25"H

Arm Dimensions:

3" Round x 43" Long

Weight:

8 lbs

Cabinet Materials:

18 ga. stainless steel

Motor:

Fractional Horsepower

Air Volume:

Up to 70 CFM

Electrical:

115/1/60, .46 amps

Sound Level:

Approx. 66 dba @ 3' from inlet

Patented Design:

U.S. PATENT #5,843,197

Quick Compare

Benchtop Sentry

|

Winged Sentry

|

Portable Sentry

|

|

|---|---|---|---|

| Cabinet Dimensions: | 6.25"L x 8"W x 8"H | 6.25"L x 8"W x 8"H | 8"L x 8"W x 8.25"H |

| Weight: | 8 lbs. | 8 lbs. | 8 lbs. |

| Electrical |

115/1/60, .3 amps 220/1/50, .2 amps |

115/1/60, .3 amps 220/1/50, .2 amps |

115/1/60, .3 amps 220/1/50, .2 amps |

| Sound Level | Approx. 62 dba @ 3' from inlet | Approx. 62 dba @ 3' from inlet | Approx. 62 dba @ 3' from inlet |

Made in the USA

Made in the USA