Tissue Culture Hood

Tissue culture hoods provide a reduced particulate environment for the study and growth of tissue cultures for many different medical, scientific, and botany applications. These ISO Class 5 clean rooms utilize positive pressure, and a laminar airflow pattern that creates a clean and controlled environment and prevents outside contamination. In addition, tissue culture hoods host a powerful filtration system equipped with the HEPA or ULPA filters brings in outside ambient air removing up to 99.95% of particles 0.3 microns and smaller for HEPA filters or 99.99997% of particles 0.12 microns or smaller for ULPA filters.

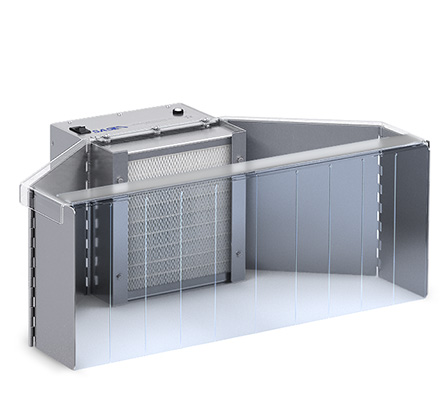

Portable Clean Rooms

The Portable Clean Room is a compact positive pressure system designed to provide exceptionally clean laminar airflow inside the hood. This system utilizes a dual stage filtration process which consists of a MERV8 pre-filter and a HEPA filter with an efficiency rating up to 99.97% efficient on particles .3 micrometers and larger. For applications requiring a higher efficiency an ULPA filter is available with an efficiency rating of up to 99.9995% at .12 micrometers.

Traditionally, companies that desired a clean sterile work space would have to convert an entire room into a HEPA filtered positive pressure area, and end up spending tens of thousands of dollars and take up excess room. However, our portable clean rooms are designed to be cost saving, by offering a compact solution that requires very little space and as much mobility as needed.

Additional Configuration

How to Clean a Tissue Culture Hood

Tissue culture hoods must be cleaned inside and around daily to prevent the buildup of foreign material that can interfere with results. Generally, cleaning is conducted from top to bottom within the hood and from the cleanest area to the dirtiest. The hood is cleaned first and then nearby areas can be focused on. To properly clean the cell culture hood, strict procedures must be implemented including cleaning, disinfecting, and applying a sporicidal agent to the inside of the hood and surfaces nearby. First, clean the hood with sterile water and low-lint cloth. Then, apply a cleaning agent to remove the remaining residue. To remove fungi, viruses, and bacteria, utilize a sterile disinfectant to properly disinfect areas. Apply a sporicidal agent and dry all surfaces. Operators must clean at the beginning of the day and the end of the day. If conducting different tissue culture applications, horizontal surfaces of the hood should be cleaned in between each to prevent cross-contaminations.

Made in the USA

Made in the USA