Say you’re developing a multiple-axis robotic movement for a biological feedstock handler that must be coordinated with both a sonic impulse and a temperature change.

Right now, that beast is far from its final form. It’s a little sprawly, has that temporary joist adhered to the top, and is not yet the sleek utensil you envision.

If it hiccoughs, it’s likely you’re going to make manual adjustments to it, even if the computer interface is proceeding apace.

Would your adjustments release the feedstock? If released, would it go airborne? Can it be inhaled? Would you want to?

Flexible, cost-effective solutions needed

Developing automation tools that manipulate biological materials is not all glamour.

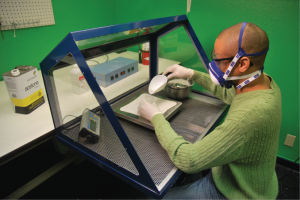

Above, a technician weighs silica on the perforated bench top of a Model 435 Portable Downdraft Bench – Sit, which pulls renegade particles down into filters that trap them below the work surface, away from his mouth and nose.

If you’re not careful, getting to perfect may involve respiratory exposure to particles and fumes that aren’t good for you or your lungs.

One method for dealing with these issues is the installation of a clean room for your beast and the addition of glove boxes for you so you can touch it when you have to. It may take up a lot of square footage and it may bruise your budget.

So, because each industrial hygiene situation is different, we offer additional engineering safety controls that may suit your particular development situation.

Three Down Draft Bench (DDB) models suitable for engineering environments

While your device is occupying its initial footprint, engineers need access to it from all angles.

An effective engineering safety control is a Model 440 Industrial Downdraft Bench.

Operate devices in development on this bench while the powerful fan/filter chassis pulls contaminants away from the product and the engineers who circle it, down into filtration media that prevent diffusion through the lab. Filtered air is returned to the room.

The benchtop of this DDB measures 48 by 30 inches, offering both elbow room and respiratory protection.

Portable DDBs: clean air, no ductwork required

Our portable DDBs offer the same powerful, contaminant-controlling fan/filter chassis as the industrial DDB — but with wheels.

You can roll our DDBs where you have space for them, and not undertake expensive ductwork remodeling just to put them where you need them.

Model 435 Portable Downdraft Bench – Stand provides respiratory protection wherever it is needed and without dedicated ductwork.

See through the plexi walls

Plexi walls make the room’s illumination available to whoever is working on the bench top. Clear windows have additional advantages – you can walk away.

Your product is all about automation of a process. Your goal is to walk away from it, confident it is performing as desired. However, during development it may not.

So the model above, with clear plexi windows, lets you steal glances at your baby from around the lab as you attack another tasks.

Talk with our Applications Specialists

Your development lab has characteristics all its own. Our Applications Specialists work with you to identify the appropriate filtration media for your processes. For example, in addition to particle filters, you may also want activated carbon filtration to capture a specific acid gas.

Give them a call at 800.799.4609 or email sales@sentryair.com. They’ll contact you if you fill out the comment form below or on our website.

Resources

Safety Rules Can’t Keep Up With Biotech Industry, NYT

http://www.nytimes.com/2010/05/28/business/28hazard.html?pagewanted=all

Environmental, Health, and Safety Guidelines for Pharmaceuticals and Biotechnology Manufacturing, International Finance Corporation, World Bank Group

http://ow.ly/Iaq6Y

Made in the USA

Made in the USA