CNC Machine Shop with Primary Mist Collectors (SS-300-MIST) and

Ambient Air Mist Collectors (SS-2000-MIST)

Benefits of mist collectors include reducing maintenance and downtime, as well as safeguarding overall shop safety and employee health for CNC machine shops. Government organizations, such as OSHA, legally require employers to meet exposure limits. Machining, milling, and grinding processes produce oil mist when metalworking fluids come in contact with tooling components and become dispersed throughout the air. Oil mist turns into oil smoke when exposed to high temperatures during processes. Oil mist and smoke create health hazards and contaminate expensive and vital CNC machine parts.

Benefits of Mist Collectors – Reduce Maintenance & Downtime

Oil mist collectors benefit CNC machines by reducing maintenance needs and downtime. The picture below shows an oil-laden fan that has been removed from a CNC machine. CNC machines lacking proper mist collectors create common and reoccurring maintenance problems soiling parts including fans, circuit boards, control panels, cooling system filters, and tooling parts1.

First, dirt and high humidity damage circuit boards and clog up cooling system filters. Once cooling system filters start to clog, airflow becomes blocked resulting in system failure or other performance issues1. The cooling system protects valuable electronic components such as the drives, power supplies, monitors, and control systems. If the cooling system does not work properly, temperatures will rise causing electronic components to become damaged and even fail to operate properly1.

Similarly, oil mist can seep into the coolant pump systems creating bacteria that deteriorate seals on the motor pumps2. Also, dirty coolant corrodes metal surfaces leading to tool degradation, accuracy problems, and declining parts quality2.

Likewise, oil mist can clog filters and coils in the shop’s HVAC or air conditioning system. High energy costs can result from over exhausting air to remove the oil mist in the ambient air3.

Furthermore, increased frequency of maintenance causes more machine downtime with a reduction in productivity. Properly controlling oil mist reduces the need for maintenance and allows production to continue on schedule. In turn, money can be saved with the reduction of the need for replacement parts and technician visits.

Benefits of Mist Collectors – Ensure General Shop Safety

In a like manner, oil mist collectors benefit overall shop safety. Lack of oil mist collectors leads to overall shop safety concerns; even in enclosed CNC machines, oil mist can escape when opening the door while loading raw materials and removing finished parts4. When oil mist escapes from CNC machines, it lands on nearby surfaces around a machine shop including walls, counters, floors, and lighting4. Oil mist on lighting makes it darker in the shop and oil on other surfaces creates more need for housekeeping3. Not only does this cause cleanliness concerns, but oil on the floor may create a slip hazard. Equally, oil mist creates a fire hazard by creating a flammable line of oil on the floor and other surfaces4.

Benefits of Mist Collectors – Protect Employee Health

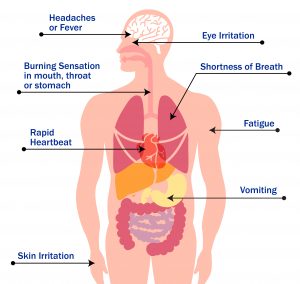

Moreover, benefits of mist collectors encompass protecting employee health from exposure to oil mist through dermal contact and inhalation5.

Dermal Exposure

First, when oil mist touches skin, contact dermatitis may form in areas of exposure5. Dermatitis causes itchy skin, rashes, and may cause the skin to crack, become red, blister and develop the appearance of bumps5. Skin conditions must be treated to prevent more serious complications from untreated dermatitis5.

Inhalation of Oil Mist

Next, inhalation of oil mist causes respiratory irritations leading to shortness of breath, vomiting, fever, rapid heartbeat, headaches, fatigue, and a burning sensation in the mouth, throat, or stomach5.Additionally, lasting respiratory conditions may develop from continual oil mist inhalation. Oil mist can activate onset asthma, cause existing asthma flare ups, and irritate airways of non-asthmatic employees5. Chronic bronchitis may develop starting with a chronic cough with phlegm and lead to lung impairment, lung damage, and heart damage5. A very serious lung disease called hypersensitivity pneumonitis causes coughing, shortness of breath, and flu like symptoms5. In the chronic stage, permanent lung scarring develops from this lifeline lung disease5.

Although less common today, oil mist exposure has been known to cause an increased risk of cancer of the rectum, pancreas, larynx, skin, scrotum, and bladder5. Modern metalworking fluids have been engineered to reduce cancer risks but because of the delay in cancer symptoms and development, there is no proof that long term oil mist exposure cancer risks have been improved5.

Benefits of Mist Collectors – Meet Legal Requirements

Additionally, benefits of mist collectors includes meeting legal requirements. Employers are legally required to restrict employee exposure to oil mist. OSHA legally limits the amount of exposure to 5 mg/m3 over 8 hour workday6. NIOSH and ACGIH recommend the same exposure limit as OSHA6.

CNC Machine Oil Mist Collectors Solutions

CNC Machine with Primary Mist Collectors (SS-300-MIST) and Ambient Air Mist Collectors (SS-2000-MIST)

Primary Control

Primary control mist collectors capture oil from the source by directly mounting on the CNC machine. These systems release filtered air back into the shop without requiring expensive external ducting or exhaust.

For more information please visit our web page on source capture mist collectors:

Secondary Control

Secondary control mist collectors hang from the air or can be mounted on stands. These units collect remaining mist in the air that may have escaped from the machine when the door opens or during cleaning. These systems also could be used in older CNC machines that do not allow for direct mounting such as open CNC machines.

For more information please visit our web page on ambient air mist collectors:

Contact us today to prolong the life of your CNC machines, reduce maintenance, and improve safety by installing a mist collector system!

Feel free to give us a call to talk to an application expert about adding an oil mist collector to your machine shop! — 1.800.799.4609

Sources

1. York, Jade & VanDeboom, Jonathan. “2 Reasons Why Your CNC Machine Will Break Down.” The Machine Runner by RepairZone, 1 Jun. 2015, http://blog.repairzone.com/2-reasons-why-your-cnc-machine-will-break-down/.

2. Hanson, Kip. “5 Reasons to Keep Machining Coolant Clean.” MSC Direct, https://www.mscdirect.com/betterMRO/metalworking/5-reasons-keep-machining-coolant-clean.

3. Richter, Alan. “Clearing the Air.” Cutting Tool Engineering, 1 Apr. 2013, https://www.ctemag.com/news/articles/clearing-air.

4. Thompson, Joe. “Make Parts, Not Health Problems.” Canadian Metalworking, 18 Aug. 2015, https://www.canadianmetalworking.com/article/metalworking/make-parts-not-health-problems.

5. Occupational Safety and Health Administration. “Metalworking Fluids: Safety and Health Best Practices Manual.” https://www.osha.gov/SLTC/metalworkingfluids/metalworkingfluids_manual.html#e.

6. Occupational Safety and Health Administration. “OSHA Annotated Table Z-1,” https://www.osha.gov/dsg/annotated-pels/tablez-1.html.

Made in the USA

Made in the USA