Polyurethane Spray Foam, used to repair concrete and for other building purposes, is just one of the many industrial uses of polyurethane foam.

What is Polyurethane Foam?

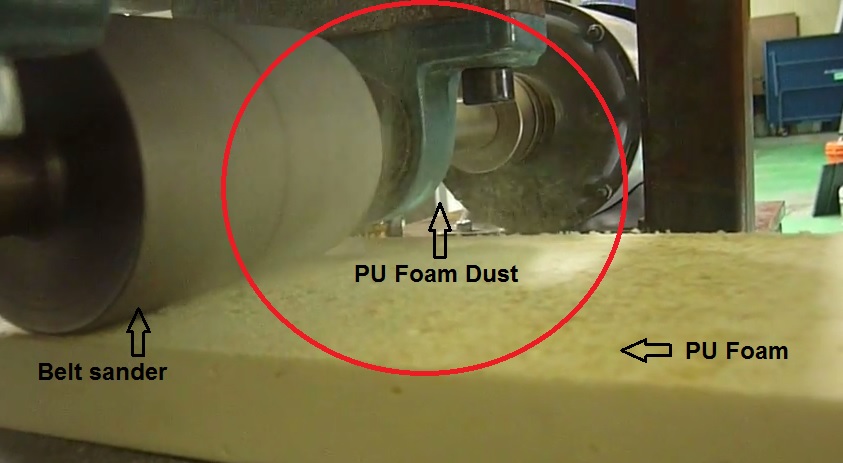

Polyurethane foam (PU) is found in many consumer and industrial products on the market today. From furniture and bedding to packaging and automotive liners, PU is known for its durability, comfort and support (American Chemistry Council). According to the Polyurethane Foam Association, approximately 1.7 billion pounds of polyurethane foam are produced and used each year in the U.S.. While there are different types and uses for foam, the basic production method is the same. Flexible PU foam is produced from a reaction of two key chemicals, a polyol and an isocyanate with water. These are mixed together vigorously in high intensity mixers in specific amounts with other ingredients, and the foam reaction begins almost immediately. Bubbles are formed and the mixture expands (PFA). Once the reaction is complete, the foam can be shaped and manipulated depending on its final use. A common method of foam manipulation is shaping through sanding or grinding. This process generates large amounts of PU dust. A short video on YouTube demonstrates a planer or belt sander smoothing out a large piece of flexible polyurethane foam. As you can see from this screenshot, dust is dispersed and accumulates in the air and on surfaces .

Video Source: http://youtu.be/vBeXalRiTBw

Polyurethane Dust Inhalation Side Effects

Thea Material Safety Data Sheet (SDS) for cured flexible PU foam highlights the following caution statements or hazards:

Cause: The primary adverse health effects of this material are related to the dust created by sanding, grinding, or cutting the cured foam. Mechanical ventilation or exhaust should be provided during this type of use/activity (Tiger Foam 2013).

Inhalation: May irritate mucous membranes causing a tightness in chest (This only if dust is created during cutting, sanding or grinding of cured foam)(Tiger Foam 2013).

Ventilation: Adequate ventilation should be utilized so that dust levels do not exceed the recommended guidelines (Tiger Foam 2013).

Polyurethane Dust Side Effects Studies

Multiple studies have focused on the potential health effects of respirable polyurethane dust.

Hospital Polyurethane Dust Study

First, this study focused on the dust emission during the cutting of polyurethane-impregnated bandages in a hospital environment (Wytch 1988). Hospital staff removed splinting bandages with a power saw and created a large amount of polyurethane dust. The airborne concentration was lower than other bandage material but the polyurethane dust was composed of tiny particles or respirable dust which can easily become and stay airborne. These tiny particles can also easily become lodged deep in the respiratory system posing additional health risks. The study found that 90% of the polyurethane dust created was considered respirable and contained fragments of polyurethane resin.

Polyurethane Dust Effect on Rodents Study

In another study, laboratory rodents where exposed by inhalation to polyurethane foam particles (20 mg/m3) for 5 days/week for 6 weeks (Thyssen 1978). Early findings showed the particles had deposited in the rodents’ respiratory bronchi and in the subpleural alveoli. Six months after initial exposure the alveolar walls started to thicken and the fibrosis progressed after nine months. At 12 months small scars developed consisting of fibrous tissue nodules.

Health Effects of Respirable Polyurethane Dust

The side effects of inhaling polyurethane dust are similar to a variety of other particulates. While OSHA and other regulatory agencies have established strict exposure limits for carcinogenic dusts like silica, a majority of general dust falls into a category called “particulates not otherwise regulated”. For the most part this encompasses respirable dust not considered to be a human carcinogen.

Exposure Limits for Particulates not Otherwise Regulated (Respirable Fraction)

| Agency | Exposure Limit | Health Factors |

| OSHA Permissible Exposure Limit (PEL) – General Industry | 5 mg/m3 TWA | Lung disease |

| National Institute for Occupational Safety and Health (NIOSH) Recommended Exposure Limit (REL) | Not established | |

| American Conference of Governmental Industrial Hygienists (ACGIH) | 3 mg/m3 (respirable particles) | Lung disease with compromised airway clearance |

| CAL/OSHA PEL | 5 mg/m3 TWA |

While “general” dust particles may not directly cause cancer, their long-term effects on the body warrant concern. Health effects mainly become apparent only after long-term exposure such as pneumoconioses. According to the CDC, pneumoconioses is a group of lung diseases resulting from the inhalation of certain dusts during workplace exposure. Side effects vary but can result in lung impairment, disability, or premature death. Effects can appear long after exposure and can easily be mistaken for a non-occupational condition (CDC).

Source Capture Engineering Controls for Polyurethane Dust

To optimized containment, respirable dusts are best captured at the source of the emission. The World Health Organization (WHO) compiled recommendations to help reduce airborne dust in the workplace and prevent exposure. Many important observations and recommendations can be found in the document including (WHO 1999):

• A dust release can be localized and only affect the immediate worker, or it may spread throughout the workplace and affect everybody else.

• Unless its generation is prevented or it is removed from the air, dust may move with ambient air and reach even persons who are remote from the source and whose exposure is unsuspected.

• Containment consists in placing a physical barrier between the substance and people, for example putting a process inside a box. It is usually necessary to have a ventilation system that keeps the enclosure under negative pressure, so that there is no emission at cracks or at points where material moves in or out of the enclosure.

Sentry Air Systems Polyurethane Dust Control Solutions

Sentry Air Systems offers a variety of source capture engineering safety controls that aid in the prevention of respirable dust exposure.

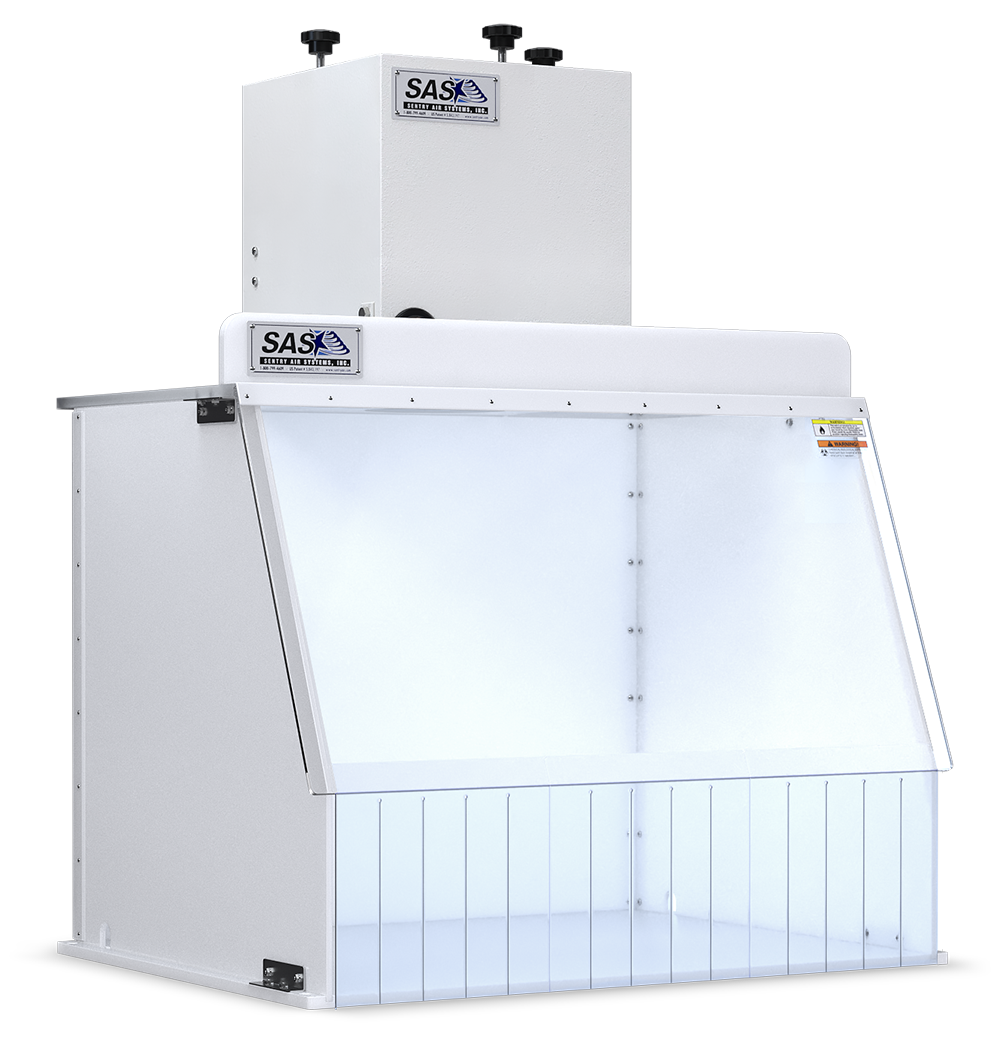

Ductless Fume Hood

Ductless Fume Hoods contain the polyurethane dust producing process in order to help prevent exposure. The system works by enclosing the activity and drawing dusts into the filtration system with a powerful fan. The high-quality filters such as HEPA remove most of the particulate from the airflow before releasing the filtered air back into the surrounding room.

Sizes Available: 18″, 24″, 30″, 40″, 50″, 60″, and 70″

Airflow: up to 350 CFM

Exhaust Fume Hood with In-line Fan

Exhaust Fume Hoods with In-line Fan connect to an external exhaust system (not included) to contain particles and remove from the airflow by directing the dust outside. The in-line fan connects to existing ductwork. The fan draws particles from under the hood into the ductwork where the air is released externally.

Sizes Available: 24″, 30″, 40″, 50″, 60″, and 70″

Airflow: 240 – 700 CFM

Industrial Fume Extractor with Cleanable Filter

The Model 500 Industrial Fume Extractor with Python hose utilizes a cleanable filter ideal for extracting airborne dusts. Working with dusts can be heavy-loading on filters but with cleanable filters once the filter is loaded, the operator can clean it using compressed air. This particular model utilizes a flexible python hose that can easily attach to machinery or near machinery for source capture extraction.

Airflow: up to 728 CFM with cleanable filters

Custom Fume Hood with Industrial Fume Extractor Combination Unit

We recently designed this conceptual drawing for a customer’s polyurethane dust application involving the grinding of flexible PU foam for automotive liners. This configuration includes a standard 70-inch wide dual exhaust hood that has been ducted to our Model 500 Industrial Air Cleaner with a dual outlet plenum and cleanable micro-pleat series filters. This custom configuration allows the operator to sand and grind the sheet of PU foam while the negative pressure system uses up to 1,300 CFM to pull dust through the ductwork and into the air cleaner. The micro-pleat series filters work to scrub the air of dust contaminants before recirculating the cleansed air back into the room. The filters easily clean with pressurized air and excess dust and waste falls into the unit’s internal dust pan allowing for easy disposal. Contact us directly to find out about other custom solutions!

Contact us today to help control occupational airborne dusts in your workplace such as polyurethane foam!

References

American Chemistry Council. (2024). Polyurethane Applications. Center for Polyurethanes Industry Pages. Retrieved from: https://www.americanchemistry.com/industry-groups/center-for-the-polyurethanes-industry-cpi/applications-benefits/polyurethane-applications.

CDC. Pneumoconioses. The National Institute for Occupational Safety and Health. Retrieved from: https://www.cdc.gov/niosh/topics/pneumoconioses/.

OSHA. Particulates Not Otherwise Regulated, Total and Respirable Dust. U.S. Department of Labor. Retrieved from: https://www.osha.gov/chemicaldata/801.

PFA. What is Flexible Polyurethane Foam? Polyurethane Foam Association. Retrieved from: https://www.osha.gov/chemicaldata/801.

Tiger Foam. (April 2013). Material Data Safety Sheet – Rigid Polyurethane Foam. Retrieved from: http://tigerfoam.com/PDF-FILES/MSDS_CURED_FOAM.pdf.

Thyssen, J. (1978). Inhalation Studies with Polyurethane Foam Dust in Relation to Respiratory Tract Carcinogenesis. PubMed. Retrieved from: https://pubmed.ncbi.nlm.nih.gov/722200/

WHO (1999). Hazard Prevention and Control in the Work Environment: Airborne Dust. Retrieved from: https://www.who.int/publications/i/item/WHO-SDE-OEH-99-14.

Wytch, R. (1988). Dust Emission During Cutting of Polyurethane-impregnated Bandages. Digital Resource Foundation for Orthotics & Prosthetics Community. Retrieved from: https://www.oandplibrary.org/poi/1988_03_155.asp.

Made in the USA

Made in the USA