Allergy Practices must follow USP 797 when compounding or mixing allergenic extracts for individual patients.

Allergy and ENT practices must follow USP 797 when mixing patient-specific allergen extracts for subcutaneous immunotherapy (ACAAI 2023). Section 21 of USP 797 details the requirements for allergen extract compounding to reduce the chance of contamination and protect the patient’s overall health. Requirements apply for mixing allergen extracts for allergy testing and regular immunotherapy. Allergists used to be exempt from USP 797 guidelines but USP specifically wrote Section 21 for compounding allergen extracts which took effect November 1, 2023 (ACAAI 2023).

What is USP 797 Section 21 the Allergy Exception?

USP 797 Section 21 outlines the safe practices for allergenic extract mixing to help protect patient safety. USP created a specific section for allergen extracts because mixing allergenic extracts varies greatly from regular compounding (ACAAI 2023). Section 21 details the requirements for personnel, garbing, facilities, cleaning, BUDs, labeling, transportation, and documentation. The purpose of USP 797 Section 21 is to help protect patient safety, help improve the sterility of extracts, and protect the reputation of allergists and ENT specialists (Fuel Medical 2023). The next section of this blog will briefly summarize the USP 797 Section 21 requirements.

USP 797 Section 21 Summary

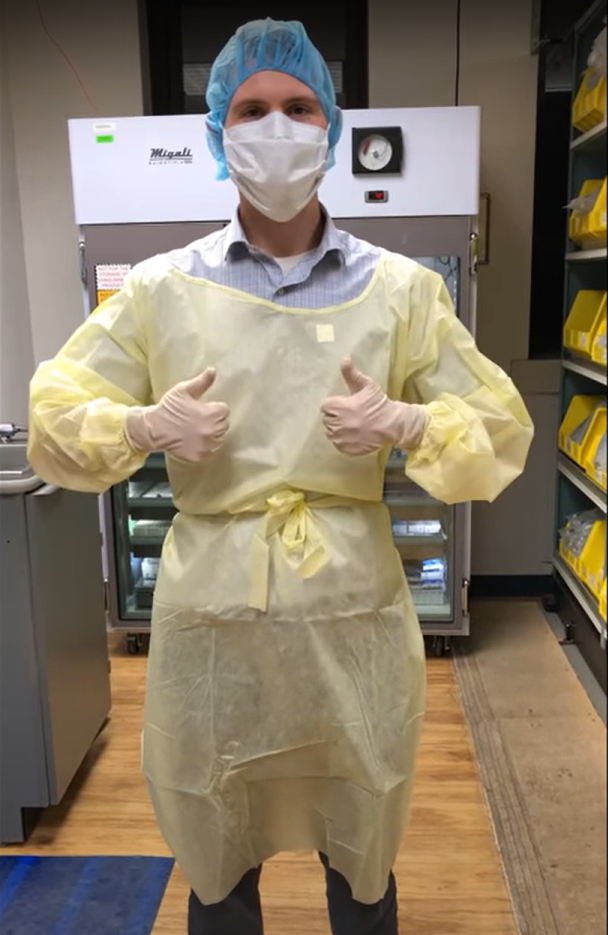

Medical worker illustrating the proper way to garb for USP 797 (Taylor 2019).

Personnel

Allergy practices must designate an individual in charge of training other personnel in USP 797 practices. Personnel training must be completed, documented, and evaluated every 12 months. Personnel that have not compounded in the past 6 months must be reevaluated to ensure comprehension (ACAAI Appendix 5).

Garbing

Proper garb must be low lint, fitted at the wrists and neck, and include head covers, masks, and sterile powder-free gloves. Personnel must rub their gloves with 70% IPA throughout compounding (ACAAI Appendix 5).

Facilities

Mixing of allergenic extracts must be completed in a specific location called the allergenic extract compounding area (AECA) or in a primary engineering control (PEC) that meets ISO Class 5 cleanroom standards (ACAAI Appendix 5). This section will be explained in further detail below (link).

Cleaning

All surfaces must be cleaned daily and when contamination is suspected. The horizontal work surface must be cleaned in between each prescription set. 70% IPA is the recommended cleaner (ACAAI Appendix 5).

BUDs

The beyond use date must not be earlier than the soonest expiration date of the allergenic extract and can’t be over a year after compounding (ACAAI Appendix 5).

Labeling

Labeling must include the patient’s name, type of extract, dilution, BUD, and required storage information (ACAAI Appendix 5).

Shipping

Transportation must deliver vials in undamaged, sterile, and stable condition (ACAAI Appendix 5).

Documentation

The designated in-charge personnel must keep all proper documentation including SOPs, training records, PEC certification reports, temperature logs, compounding records, adverse events, and investigations/corrective actions (ACAAI Appendix 5).

USP 797 Allergenic Extracts Compounding Facility Requirements

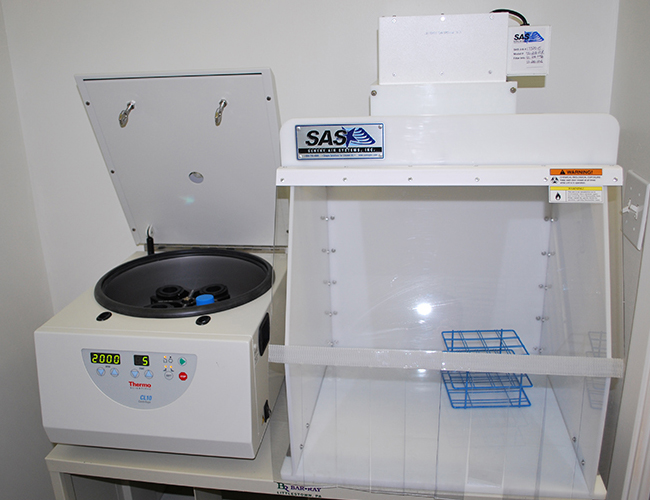

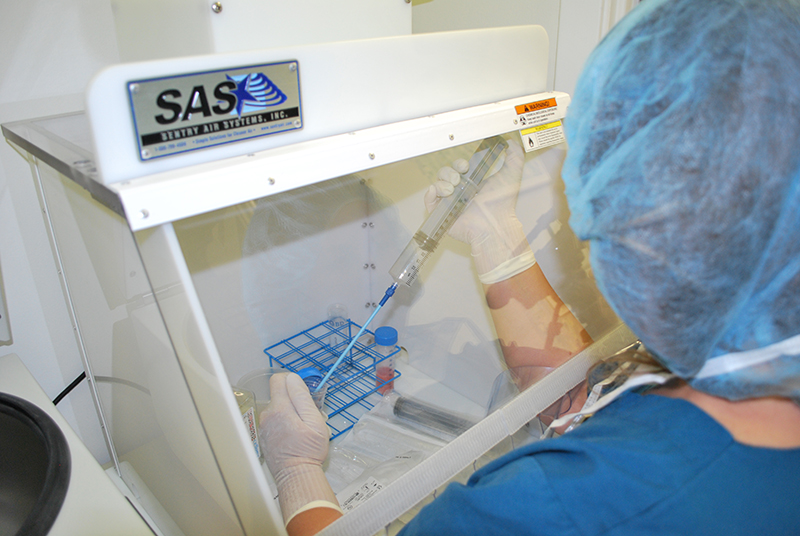

The operator uses a Portable Clean Room (ISO Class 5 Cleanroom) to protect from outside contamination.

Mixing or compounding of allergen extracts for individual patients must be conducted in an allergenic extract compounding area (AECA) or a primary engineering control (PEC) that meets ISO Class 5. The American College of Allergy, Asthma & Immunology recommends implementing an AECA due to the simplicity but PECs offer greater protection and patient safety with a more sterile environment (ACAAI 2023). AECAs also require extensive cleaning as all surfaces have to be sterilized including the walls, ceiling, floor, work surfaces, etc. PECs have a much smaller surface area making cleaning easier for personnel.

ISO Class 5 PEC Advantages

First, ISO Class 5 Cleanrooms utilize HEPA or ULPA filters to supply filtered air to the workspace to reduce outside contamination. To meet ISO Class 5 cleanroom standards, the filtered air within the hood must have less than 3,520 particles per cubic meter sized 0.5 microns (Farquharson 2023). Likewise, these systems offer a compact controlled space that takes up less room ideal for smaller practices. Also, ISO Class 5 PECs are easier to clean than AECAs due to less surface area.

Sentry Air Solutions for ISO Class 5 PECs

Portable Clean Rooms from Sentry Air provide a primary engineering control that meet ISO Class 5 cleanroom standards. These systems offer a cleanroom in a portable package with a smaller footprint. Our Portable Clean Room line supplies HEPA or ULPA-filtered air to the workspace to help reduce outside contamination.

Benefits of Portable Clean Rooms

• ISO Class 5 cleanroom

• Each hood tested to ensure ISO Class 5 standards

• PAO testing capable

• Portable

• Small Footprint

• Supplies HEPA or ULPA filtered air

• Made in the USA

• Backed by expert support

• Variety of sizes

• Economical clean room solution

• Easy filter change

Comparing Portable Clean Room Models

Help improve safety for compounding allergenic extracts with ISO Class 5 Portable Clean Rooms from Sentry Air. Contact us today!

Related Blogs

• Portable Clean Rooms – Generation II – New Line from Sentry Air

• USP 797 Guidelines for IV Bag Preparation

• Help Prevent PCR Contamination with Laminar Flow Hoods

References

ACAAI. (October 2023). 2023 – USP 797 Implementation Nov. 1. American College of Allergy, Asthma, & Immunology. Retrieved from: https://college.acaai.org/2023-usp-797-implementation-nov-1/.

ACAAI. Appendix 5. USP Section 21 – Compounding Allergenic Extracts. American College of Allergy, Asthma, & Immunology. Retrieved from: https://college.acaai.org/wp-content/uploads/2021/01/Section-21-USP-Compounding-Allergenic-Extracts.pdf

Farquharson, G., Goldschmidt, N. (March/April 2017). Understanding Cleanliness Classifications for Life Science Facilities. ISPE. Retrieved from: https://ispe.org/pharmaceutical-engineering/march-april-2017/understanding-cleanliness-classifications-life-science.

Fuel Medical. (October 2023). Managing Your Allergy Department’s Workflow with USP 797. Retrieved from: https://fuelmedical.com/managing-your-allergy-departments-workflow-with-usp-797/.

Taylor, Daniel. (2019, Jan 20). USP 797: How to Garb. Accessed May 30, 2024. https://youtu.be/u82S14pxF3I?si=o0iVJb_wZ9PxLSpm.

Made in the USA

Made in the USA