Science class with improved safety features: Ductless Fume Hoods and a UV Air Cleaner

To improve safety in the science classroom, educational facilities should utilize Fume Hoods and Air Cleaners. Fume Hoods, such as Ductless Fume Hoods or Exhaust Hoods, provide the first layer of defense against harmful fumes and particulate created from experiments, demonstrations, or studies. Chemistry Fume Hoods can also help protect from other hazards such as chemical or thermal burns and chemical adsorption. Air Cleaners provide a secondary safety control in the science classroom by filtering airborne pollutants and microorganisms overall improving the classroom or lab air quality.

Science Classroom Fume Hood Applications

Fume Hoods provide a vital safety control for a variety of purposes in the science classroom and higher education laboratories including:

• Chemistry demonstrations

• Observing students performing chemistry experiments

• Evaporating solvents or using solvents/adhesives

• Biological applications and studies

• Microscopy

• Slide preparation

Educational Fume Hood Regulations

Fume Hoods used in an educational setting must follow regulations set by the government and educational associations including OSHA, the university or school safety board, and the National Science Teaching Association (NSTA). Adhering to strict safety guidelines helps optimize fume hood performance in order to help improve safety in the science classroom.

OSHA Chemical Fume Hood Regulations

Occupational Safety and Health Association, OSHA, regulates workplace exposure of harmful substances but these standards also apply to schools for faculty and student safety. For all chemical labs, OSHA has Standard 29 CFR 1.910.1450 offering guidance on proper chemical handling and safety (OSHA, 2019). This standard suggests creating a chemical safety plan, ensuring proper ventilation, installing proper engineering controls or fume hoods, and utilizing PPE (OSHA, 2019). Also, certain chemical fumes pose more serious health risks and require lower thresholds of exposure to reduce potential harm. Lab safety managers need to be aware of the chemicals in use, association exposure limits, and methods of reducing exposure. Refer to OSHA’s Permissible Exposure Limits – Annotated Tables for the legal exposure limit for each chemical (OSHA, n.d.).

University Lab Requirements

Universities set their own fume hood safety requirements and certification process. For example, Stanford requires all fume hoods to have an average face velocity of 100 FPM and a minimum of 70 FPM at any time (Stanford, n.d.). Also, Stanford has a clearly defined Laboratory Fume Hoods Performance Criteria and Certification Protocol (Stanford, 2021). This extensive document details the certification process and requires annual fume hood certification. Contact your University’s safety officer for institution-specific guidelines on fume hoods.

NSTA Science Class Safety

The National Science Teaching Association (NSTA) offers science educators and professionals best practices and safety guidelines for teaching science. For fume hoods, NSTA suggests using equipment that has been inspected following the National Fire Protection Association (NFPA) 45 Standard (Roy, 2021). The NFPA 45 Standard requires fume hoods to provide continuous ventilation, be constructed of a material that meets chemical and application requirements, and use an airflow device to ensure proper ventilation (NFPA, 2019).

10 Tips for Classroom Fume Hood Safety

Safety recommendations and guidelines vary by the educational institution but mainly educators can improve safety in the science classroom and proper fume hood operation by following these 10 tips.

1. Always test that the fume hood is working properly before use (Wright State University, 2019).

2. Notify the safety or lab manager if airflow suddenly changes or if the fume hood is not working properly (Wright State University, 2019).

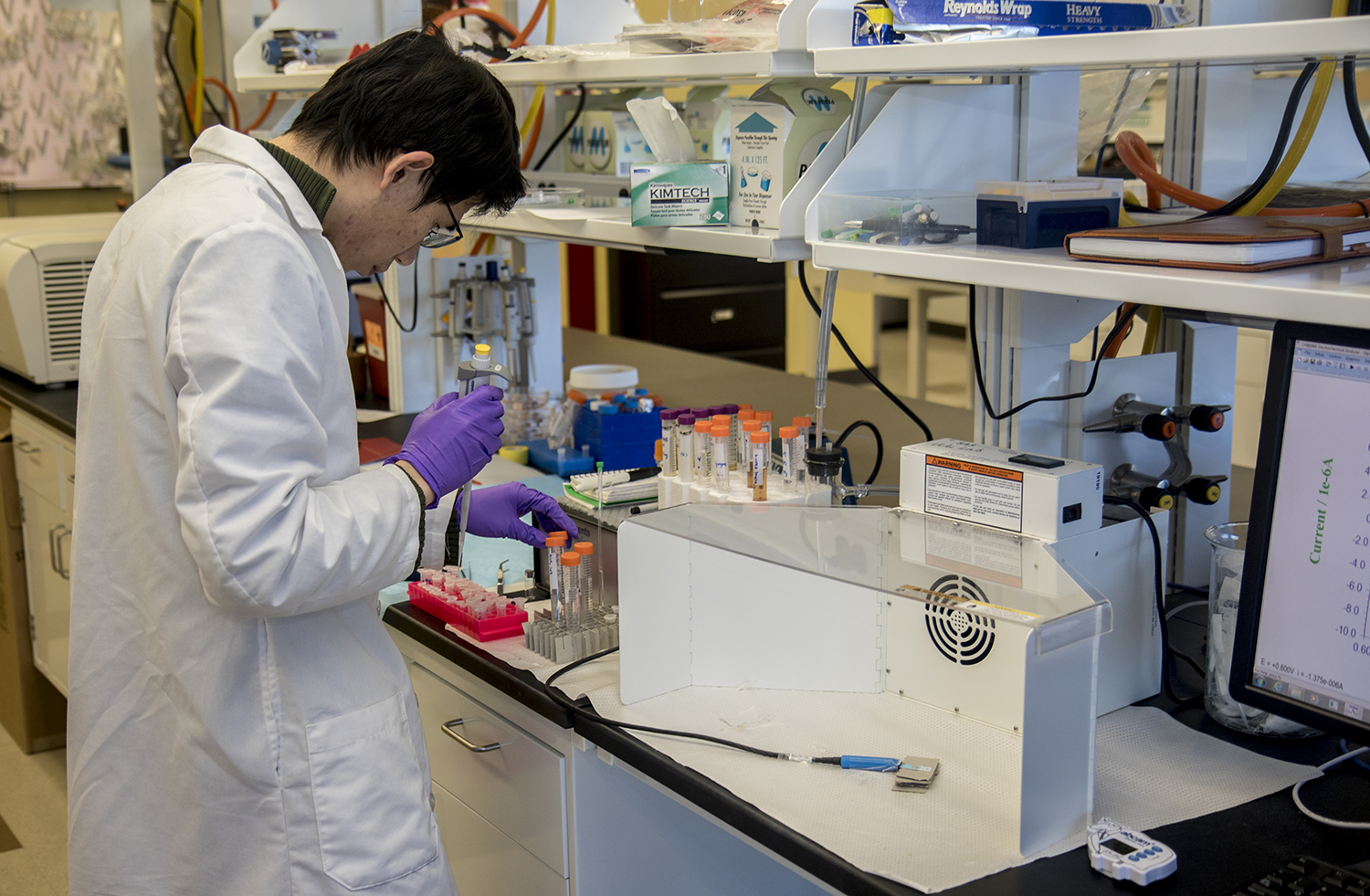

3. Always use appropriate personal protection equipment (PPE) such as goggles, gloves, and lab coats (Wright State University, 2019).

4. Never stand inside the fume hood or place your head inside (Wright State University, 2019).

5. Clean up spills right away (Lab Manager, 2011).

6. Review a chemical’s Material Safety Data Sheet (MSDS) to ensure you are using the proper filter and fume hood type for the application (Wright State University, 2019).

7. Never use the fume hood for storage of chemicals (Wright State University, 2019).

8. Keep objects at least 6 inches inside the fume hood to optimize proper fume extraction (EHS UC Berkeley, 2008).

9. Use the proper sash placement and keep the sash closed when not in use (Wright State University, 2019).

10. Test fume hoods periodically for proper airflow and operation (Wright State University, 2019).

Improving Classroom Air Quality

Improving the classroom air quality with Air Cleaners can improve student performance and reduce disease transmission.

Improving the overall classroom air quality can provide many benefits to the students and staff. Not only does it help reduce exposure to harmful substances but, studies have shown that with increased air changes and ventilation, students have improved test scores, concentration, and overall academic success (Gout et al.,2022). Also, improved indoor environmental quality (IEQ) helps reduce disease transmission in turn reducing healthcare costs, absenteeism, and illness (Gout et al.,2022). Similarly, school staff and faculty will feel reassured with extra respiratory protection leading to improved morale and reduced absences.

Science Class Safety Solutions

Science class safety can be vastly improved by utilizing proper engineering controls that help improve air quality. Fume Hoods provide the vital first layer of defense against exposure to harmful fumes and particulate. Depending on the application and chemicals used, fume hoods are available as a ductless design that filters out contaminants and recirculates the air, or as an exhaust design that externally ducts fumes and particulate. Air Cleaners offer a secondary control for airborne particles, germs, and other microorganisms.

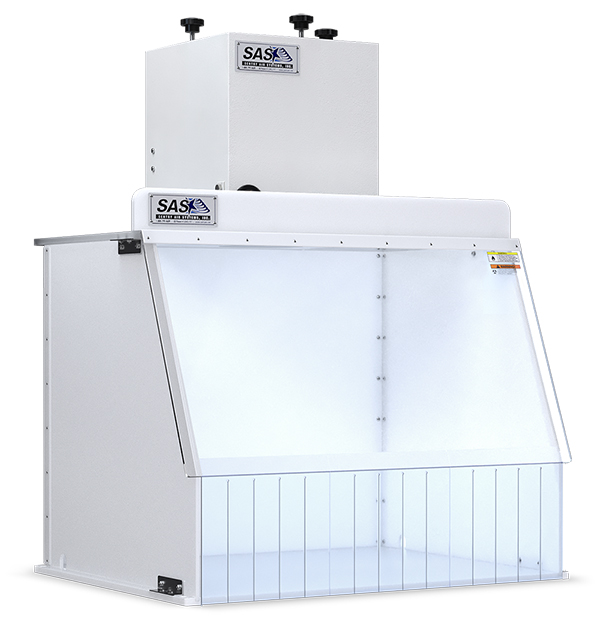

Classroom Ductless Fume Hoods

Ductless Fume Hoods provide fume containment and extraction by removing most of them from the airflow and releasing the filtered air back into the surrounding room. The ductless design removes the need for ductwork and make-up air in turn reducing installation cost and time.

Best Use: Science experiments and demonstrations that emit particulate and/or fumes. Best for use with chemicals that are easy to filter.

Benefits:

• Compact and portable

• Easy to install

• Long-lasting filters

• Reliable operation

• Clear construction options available ideal for classroom demonstrations

Widths: 12”, 18”, 24”, 30”, 40”, 50”, 60”, and 70” (Custom widths available)

Filters Available: HEPA Filter [up to 99.97% efficiency on particles 0.3 microns and larger], ASHRAE Filter [up to 95% efficiency on particles 0.5 microns and larger], Activated Carbon, and specialty-blended filtration [i.e. acid gas, mercury, aldehyde, and ammonia]. (Dual filter set-up available for applications that emit both fumes and particulate)

Approximate Airflow & Inlet Velocities by Model

| Model | Airflow* | Inlet Velocity (CPF + HEPA)** | Inlet Velocity (CPF + Activated Carbon)** |

| 12” & 18” SS-212-DCH SS-218-DCH |

80 CFM | 100 FPM | 60 FPM |

| 24” SS-324-DCH |

350 CFM | 100 FPM | 60 FPM |

| 30” & 40” SS-330-DCH SS-340-DCH |

350 CFM | 130 FPM | 115 FPM |

| 50” SS-350-DCH |

350 CFM | 105 FPM | 80 FPM |

| 60” SS-360-DCH |

350 CFM | 100 FPM | 70 FPM |

| 70” Dual SS-370-DCH-D |

350 CFM per blower |

100 FPM | 70 FPM |

* Up to figure, airflow may vary depending on filter media, **CPF = Carbon Pre-Filter

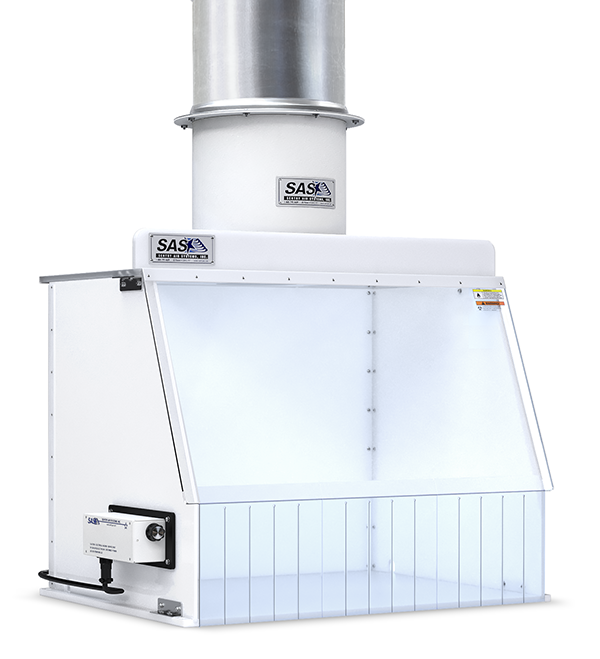

Chemistry Class Exhaust Fume Hoods

Exhaust or Ducted Fume Hoods provide fume control by directing fumes into the ductwork and releasing the air outside of the building. Exhaust fume hoods offer the best protection for volatile chemicals with noxious fumes. Please note: The safety manager or end user must refer to local, state, and federal guidelines for external ducting to ensure compliance.

Best Use: For chemical use especially ones that have a low odor threshold, are hard to filter, or produce noxious fumes

Benefits:

• Includes a powerful in-line fan with variable speed control

• Made of all chemical resistant materials

• Continuous fume removal

• Reliable operation

Widths: 24”, 30”, 40”, 50”, 60”, and 70” (Custom widths available)

Air Volume: 240 – 700 CFM (approximately)

Classroom Air Cleaners

Ambient Air Cleaners provide a secondary engineering control that helps remove airborne contaminants and particles from the air flow. These systems can be mounted on the ceiling, the wall, a table, or on a fume extractor stand (not included). Sentry Air offers two variations depending on the airflow needed and the size of the room.

Best Use: General room air filtration

Benefits:

• Low maintenance

• Easy-to-install

• Powerful airflow

| Model | Model 700 Ambient Air Cleaner SS-700-FH |

Model 2000 Ambient Air Cleaner SS-2000-FH |

| Air Volume | Up to 770 CFM | Up to 2,000 CFM |

| Filters | Quad Filter Chamber: pre-filter, 2 main filters, and post-filter

Main filters available: HEPA Filter [up to 99.97% efficiency on particles 0.3 microns and larger], ASHRAE Filter [up to 95% efficiency on particles 0.5 microns and larger], Activated Carbon, and specialty-blended filtration [i.e. acid gas, mercury, aldehyde, and ammonia]. |

Dual-Stage: MERV 8 pre-filter and MERV 15 bag filter [MERV 8 – up to 70% efficiency on particles 3.0 – 10 microns; MERV 15 – 0.30 – 1.0 microns less than or equal to 85% efficiency, 1.0 – 3.0 microns less than or equal to 90% efficiency, 3.0 -10.0 microns less than or equal to 95% efficiency] (EPA, 2022) |

Classroom UV Air Cleaners

For added protection against diseases and microorganisms, the GermKiller UV Air Sanitizer helps cleanse the air of contaminants using powerful UV-C lights. This system works by drawing ambient air into the system, filters out large particles with a pre-filter, and processes the air with two UV-C bulbs. The UV-C light deactivates microorganisms and releases the cleansed air back into the surrounding room.

Best Use: Help prevent disease or microorganism’s transmission

Benefits:

• Easy-to-install – no ductwork required

• Adjustable fan speed

• Deactivates DNA in microorganisms

• Four-way louvre helps direct outgoing airflow

Air Volume: 300, 375, or 450 CFM

Help improve science class safety and classroom air quality with Fume Hoods and Air Cleaners from Sentry Air. Contact us today to get started!

Call us today! – 1-800-7999-4609 • 1-713-690-2153

Related Blogs

• Laboratory Fume Hoods

• Rotary Evaporator Fume Control

• COVID-19 Air Filtration Solutions for Schools

• 5 Air Quality Tips to Improve Work Efficiency

Sources

EHS UC Berkeley. (2008, October). Proper Use of a Fume Hood Video. Video retrieved from https://youtu.be/A4AHxLnByts

EPA. (2022, July). What is a MERV rating? Indoor Air Quality (IAQ). Retrieved from https://www.epa.gov/indoor-air-quality-iaq/what-merv-rating

Gout, Elise; Modaffari, Jamil; Rosenthal, Jill; Snover, Tara. (2022, August). School Air Filtration and Ventilation Strategies To Improve Health, Education, Equity, and Environmental Outcomes. Center for American Progress. Retrieved from https://www.americanprogress.org/article/school-air-filtration-and-ventilation-strategies-to-improve-health-education-equity-and-environmental-outcomes/

Lab Manager. (2011, September). 5 Steps to Using a Fume Hood. Lab Health and Safety. Retrieved from https://www.labmanager.com/lab-health-and-safety/5-steps-to-using-a-fume-hood-18161

NFPA. (2019). NFPA 45 Standard on Fire Protection for Laboratories Using Chemicals. Retrieved from https://link.nfpa.org/free-access/publications/45/2019

OSHA. (2019, May). 1910.1450 Occupational exposure to hazardous chemicals in laboratories. Code of Federal Regulations. Retrieved from https://www.ecfr.gov/current/title-29/subtitle-B/chapter-XVII/part-1910/subpart-Z/section-1910.1450

OSHA. (n.d.). Permissible Exposure Limits – Annotated Tables. United States Department of Labor. Retrieved from https://www.osha.gov/annotated-pels/table-z-1

Roy, Ken. (2021, November). Lab Safety and the ‘Dirty Dozen’. National Science Teaching Association. [Web log post]. Retrieved from https://www.nsta.org/blog/lab-safety-and-dirty-dozen

Stanford. (2021, November). Laboratory Ventilation Management Program Appendix 10.2.1. Stanford Environmental Health & Safety. Retrieved from https://ehs.stanford.edu/manual/fume-hood-testing-and-performance-standards

Stanford. (n.d.) 3.10 Fume Hood Construction, Installation & Performance. Stanford Environmental Health & Safety. Retrieved from https://ehs.stanford.edu/manual/laboratory-standard-design-guidelines/fume-hood-construction-installation-performance

Wright State University. (2019, February). Fume Hood Operation Dos and DON’Ts. Environmental Health and Safety. Retrieved from https://www.wright.edu/environmental-health-and-safety/article/fume-hood-operation-dos-and-donts

Made in the USA

Made in the USA