To protect the safety of the patient, infusion clinics and other healthcare facilities should always spike IV bags in an ISO Class 5 clean room environment. Following best practices for spiking IV bags for immediate use helps prevent external contamination and protect medication quality.

To protect the safety of the patient, infusion clinics and other healthcare facilities should always spike IV bags in an ISO Class 5 clean room environment. Following best practices for spiking IV bags for immediate use helps prevent external contamination and protect medication quality.

What is spiking an IV bag?

Healthcare worker adjusts IV bag after spiking for

patient infusion (Source)

Spiking an intravenous (IV) bag occurs when a healthcare professional punctures an IV bag for injecting medication or the attachment of IV tubes for patient infusion (Nurse Sarah). Healthcare facilities that spike IV bags include infusion clinics, mobile IV clinics, patient treatment centers, hospitals, veterinarians, and more. During this process, contamination may occur from outside germs, dust, or particulate. Safe preparation procedures can help ensure the quality of the IV medication and protect the patient’s safety.

Aseptic Techniques for Spiking IV Bags

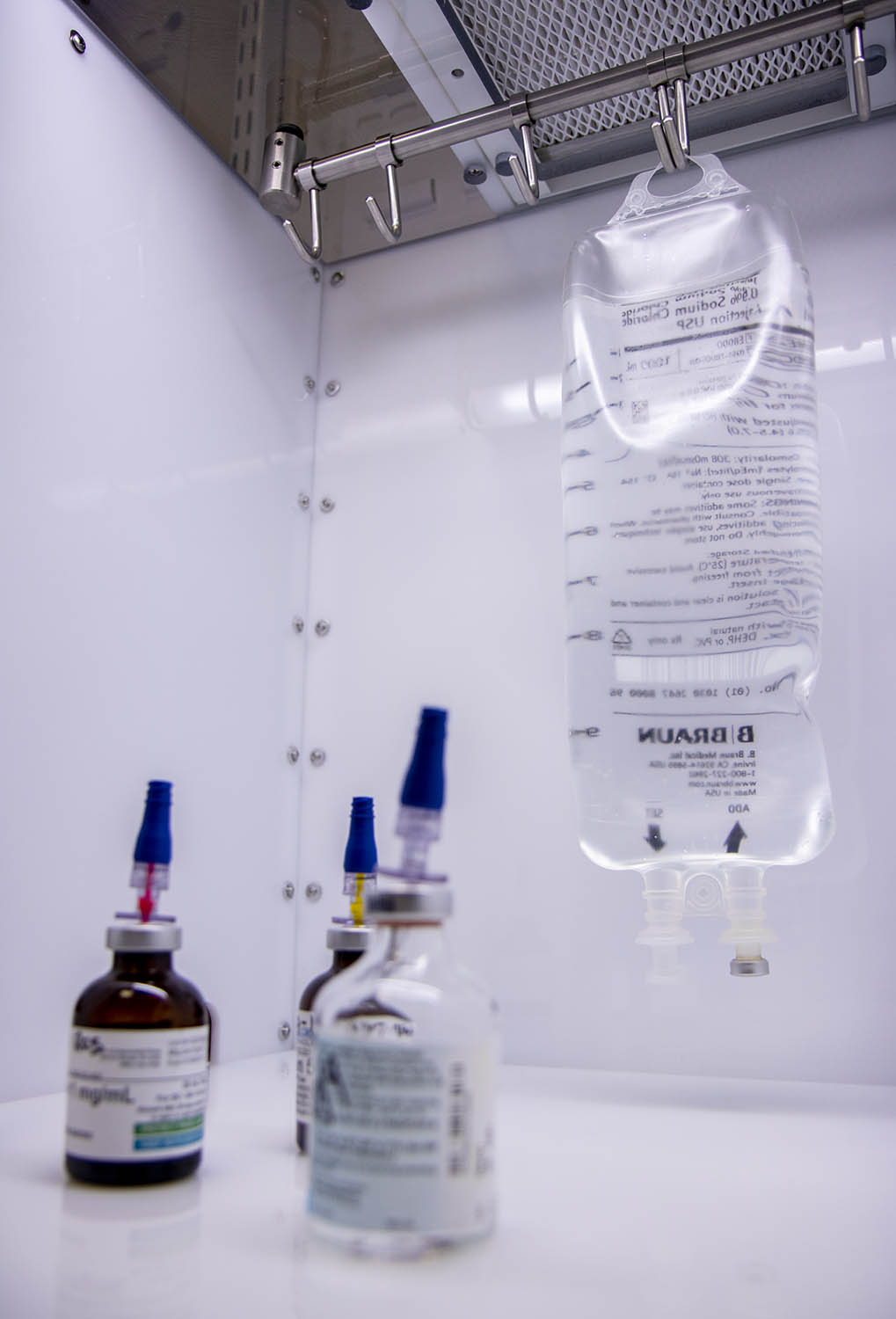

IV Hoods provide easy storage for after advance spiking of IV bags.

When spiking IV bags for immediate use, healthcare professionals should follow aseptic techniques to help prevent external contamination and protect medication quality.

According to the Joint Commission, aseptic techniques refer to the methods to prevent contamination with microorganisms. When spiking IV bags, microorganisms, and dust could contaminate the medication posing a health risk to susceptible patients. Aseptic techniques include:

Utilization of Barriers – Use barriers to prevent the transfer of microorganisms from healthcare personnel and the environment to the patient (Joint Commission 2013). Includes sterile gloves, sterile gowns, sterile drapes, and masks.

Patient & Equipment Preparation – antiseptic skin preparation, sterile instruments, sterile equipment, and sterile devices.

Environmental Controls – Use an environmentally controlled workspace with reduced particulate air such as an ISO Class 5 Clean Room.

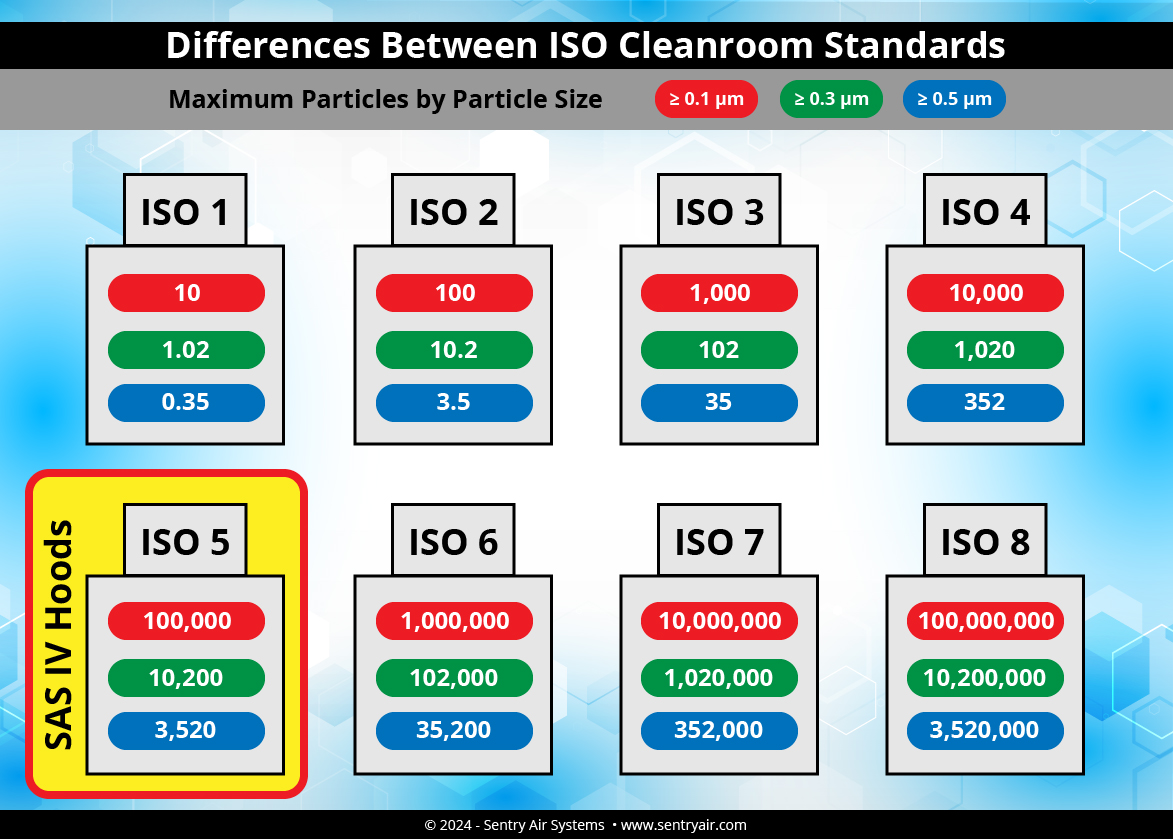

What is an ISO Class 5 Cleanroom?

The International Organization for Standardization (ISO) sets guidelines for the maximum number of particles allowed per cubic meter in order to meet the standardization. The chart below illustrates the differences between ISO 1 – ISO 8 Cleanrooms. Only particle sizes of 0.1 µm, 0.3 µm, and 0.5 µm have been listed below but the standardization also includes particle sizes of 0.2 µm, 1 µm, and 5 µm (American Cleanroom).

ISO Class 5 Clean Room Solutions for Spiking IV Bags

Portable IV Hoods provide an ISO Class 5 cleanroom

environment in a compact and easy to install package.

IV Hoods provide an ISO Class 5 Clean Room ideal for healthcare professionals to safely prepare and spike IV bags. These compact and portable units offer easy installation while still providing vital protection. Converting an entire room to ISO Class 5 Cleanroom environment can be difficult and costly expenditure. IV Hoods provide the necessary safety precautions in an economical and compact package that can be utilized in any department. Also, IV hoods provide convenient IV bag racks to allow healthcare professionals to prepare up to 7 or 10 bags for immediate use.

How do IV Hoods work?

1. A powerful fan pulls ambient air containing particulate and other contaminants into the filtration system.

2. A MERV 8 Pre-Filter processes the air and captures some of the particles.

3. The air passes through a final HEPA or ULPA filter removing most of the particulate from the ambient air.

4. The system discharges the filtered air into the work area of the hood in a vertical laminar flow pattern, creating a reduced particulate environment.

IV Hood – Portable Clean Room Hood

Help preserve patient safety and medication quality by preparing IV bags in an ISO Class 5 Clean Room certified Portable Clean Room System.

Call us today at 1-800-799-4609

Related Blogs

• USP 797 Guidelines for IV Bag Preparation

• Proper IV Bag and Medication Preparation Can Help Save Lives

• IV Bag Preparation Best Practices Utilizing ISO Class 5 Laminar Flow Hoods

• Portable Clean Rooms – Generation II – New Line from Sentry Air

• Help Prevent PCR Contamination with Laminar Flow Hoods

Sources

Nurse Sarah. “How to Spike and Prime and IV Bag.” RegisteredNurseRN.com. Retrieved on October 15, 2024 from https://www.registerednursern.com/how-to-spike-and-prime-an-iv-bag/.

The Joint Commission. Preventing Central Line–Associated Bloodstream Infections: Useful Tools, An International Perspective. Nov 20, 2013. Accessed October 15, 2024. http://www.jointcommission.org/CLABSIToolkit.

“American Cleanroom Systems presents Cleanroom Classifications.” American Cleanroom Systems, 2021. https://www.americancleanrooms.com/cleanroom-classifications/.

Made in the USA

Made in the USA