Food processing facilities, like the one pictured above, can benefit from using fume extractors and air filtration systems to improve the indoor air quality.

In the food processing industry, monitoring indoor air quality (IAQ) plays a vital role in helping to prevent food contamination and preserving employee health. Poor indoor air quality in food processing or production facilities can lead to foodborne illnesses for consumers and occupational asthma for workers. Food processing facilities can benefit from improving indoor air quality using portable fume extraction systems.

Food Processing Facilities Indoor Air Quality Concerns

Food Contamination

Poor indoor air quality can lead to contaminated food due to airborne contaminants such as bacteria (salmonella, e. coli, listeria, etc.), viruses, pollen, mold, and dust (WHO 2024). Airborne microbes can drastically affect the food’s quality and shelf life. Eating contaminated food can lead to foodborne illnesses. According to WHO, foodborne diseases are caused when food becomes contaminated during production, delivery, and consumption (WHO 2024). WHO estimates that 1 in 10 people fall ill from contaminated food every year which has led to 420,000 deaths. To protect the customer’s safety and company reputation, precautions must be taken to prevent food contamination.

Employee Respiratory Health

The food production process exposes employees to harmful particulate such as spices, flour, and other food dust as well as fumes such as pesticides, fumigants, and other VOCs (Piab 2023). Exposure should be minimized to protect employees’ respiratory health and reduce the chance of developing occupational asthma. The leading factors that cause occupational asthma in food processing facilities are poor ventilation systems, lack of safety training for PPE, and individual risk factors (Md Zamari 2023).

Food Safety Modernization Act

FDA’s Food Safety Modernization Act suggests that food processing facilities implement preventative contrls to help prevent food contamination.

The FDA enacted the Food Safety Modernization Act in 2015 to help prevent foodborne illnesses and improve overall food safety. In this law, the FDA recommends food processing facilities evaluate potential hazards that affect food quality (FDA 2017). Once the risks are identified, facilities should implement preventative controls to minimize occurrence (FDA 2017). Air filtration systems can act as a preventative measure by removing airborne contaminants from the airflow such as biological, physical, chemical, natural toxins, allergens, and more.

Preventative Engineering Controls for Food Processing Facilities

Food processing workers using a portable fume extractor to help remove irritating airborne particulate such as spice dust.

Fume extractors, air filtration systems, and ductless fume hoods can help facilities maintain safer indoor air quality and reduce the chance of food contamination and employee respiratory exposure. These systems draw airborne contaminants into the filtration systems and release filtered air back into the workspace. The filtration system utilizes high-quality filters such as HEPA, ASHRAE, and ULPA for particulate and Activated Carbon and specialty blended filter media for odors and chemical fumes. A combination of both can be used for applications that emit both particulate and fumes. For the food processing industry, Sentry Air Systems offers a food-grade stainless steel fume extractor and ductless fume hood.

Stainless Steel in the Food Processing Industry

The Stainless Steel Fume Extractor and Ductless Fume Hood from Sentry Air are constructed of food-grade stainless steel similar to this food processing equipment from a wine processing facility.

Food-grade stainless steel (316 & 304) offers many benefits to food processing facilities. 316 & 304 stainless steel provides a strong and versatile option that helps prevent food contamination (Carter 2023). Most food processing equipment (like the picture on the right) uses stainless steel making it a great choice for food processing fume extractors. Other benefits include (Carter 2023):

• Easy to clean smooth surface

• High quality and reliable

• Able to handle acids and resistant to acid corrosion

• Neutral surface that doesn’t pick up odors

• Antibacterial

For fume extractors and ductless fume hoods, food-grade stainless steel construction provides a smooth surface for easy cleaning and disinfecting. Also, the surface offers antibacterial properties that help prevent food contamination.

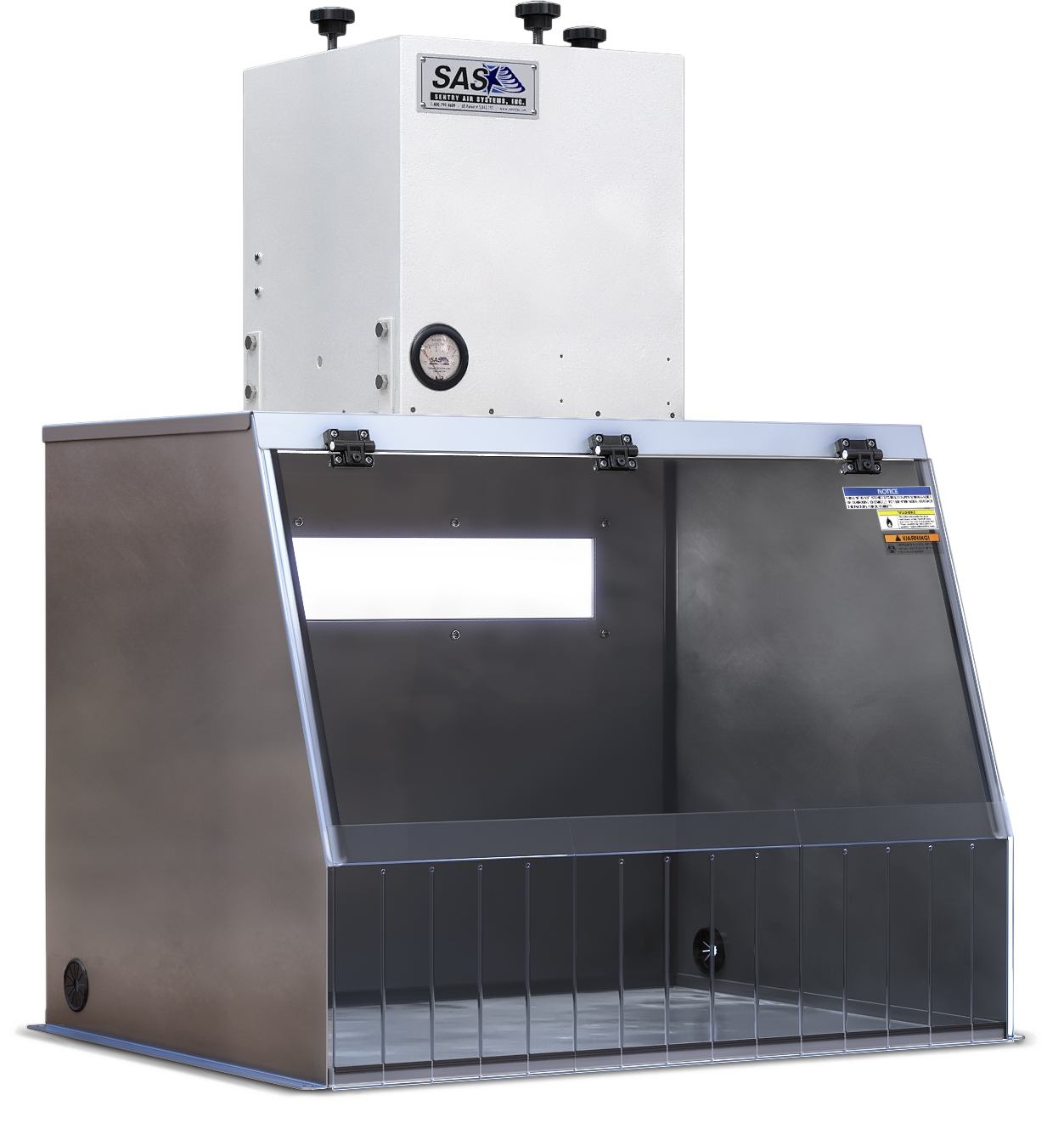

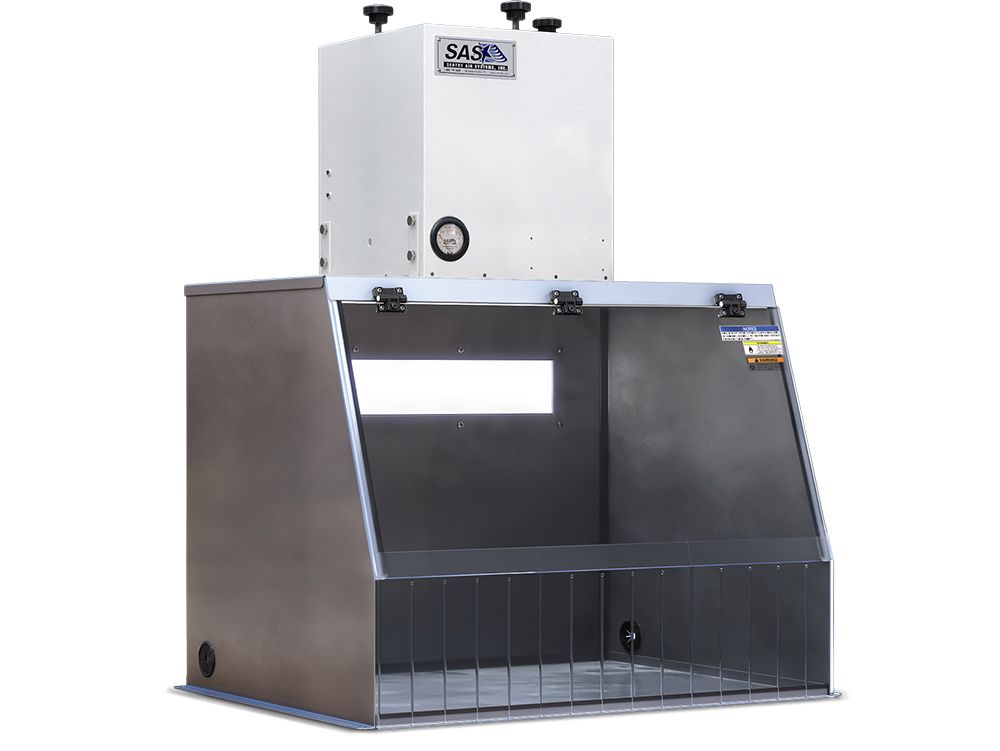

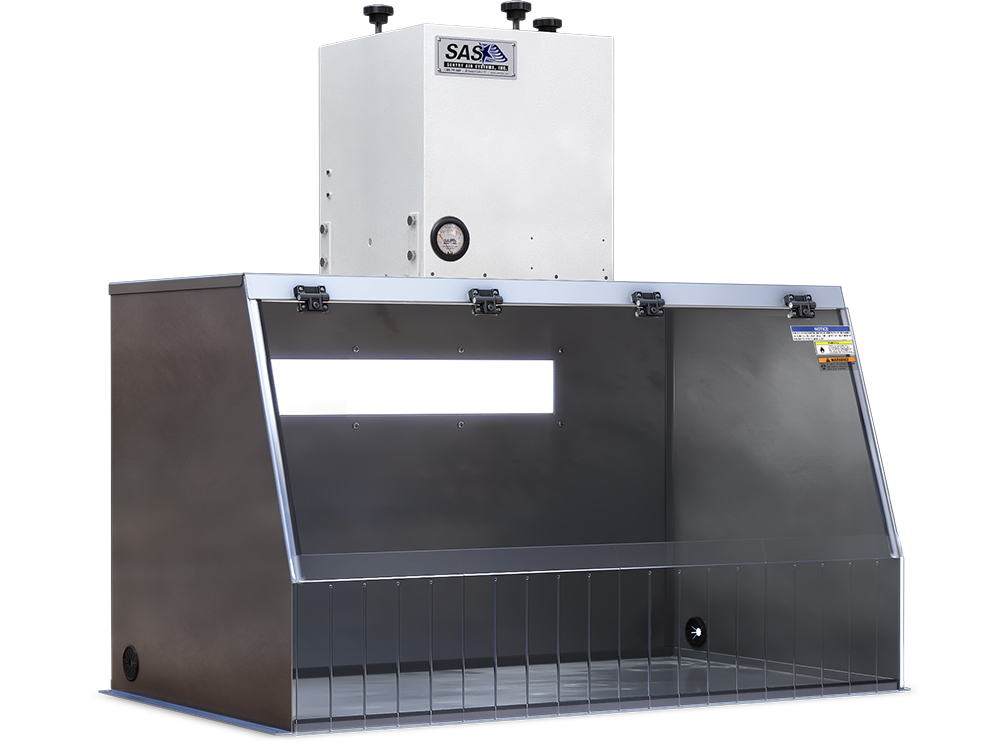

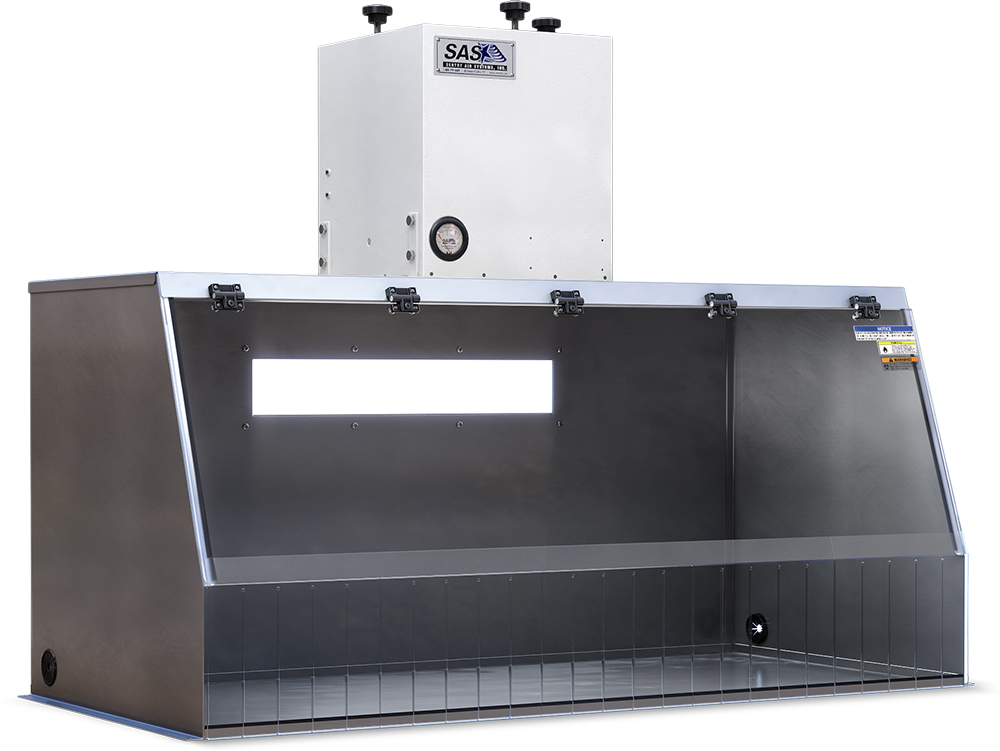

Stainless Steel Engineering Controls for the Food Processing Industry

Sentry Air offers reliable air cleaning tools constructed of food-grade stainless steel ideal for the food processing industry. Our popular Model 300 and Model 400 Portable Fume Extractors are now available in 316 Stainless Steel (food and medical grade). Similarly, our trusted ductless fume hood is available in food-grade/medical-grade stainless steel in the most popular widths – 30”, 40”, and 50”. These robust systems offer the same powerful airflow as the original models but provide additional benefits to the food processing industry.

Stainless Steel Engineering Controls Benefits

• Easy to clean and disinfect

• Meets food industry standards with 316 and 304 stainless steel construction

• Durable for acid-based environments

• Ideal for sensitive applications

• Quick lead times – 5 business days

• Made in the USA

• High quality filtration options

• Backed expert support – application specialists with years of experience will consult you to determine the best-suited solution and ensure filter efficiency.

Stainless Steel Engineering Controls Applications

• Ingredient food labs

• Food production and processing

• Applications that use corrosive chemicals

• Pharmaceutical powder transfer

• Variety of medical applications involving fumes and dust

Stainless Steel Portable Fume Extractor

The Model 300 and 400 Stainless Steel Portable Fume Extractors utilize an adjustable self-supportive capture hose that can easily be maneuvered near the fume or particulate source. These systems move easily to a different location due to portability features including heavy-duty casters and a portability handle. The Stainless Steel Fume Extractor includes a variable speed controller and a quick “no tool” filter change. This easy-to-use fume extractor provides flexibility and reliable performance.

Technical Specifications

| Picture |  |

|

|

| Model/Part Number | 300 SS-300-PFS-ST |

400 SS-400-PFS-ST |

450 SS-450-PFS-ST |

| Cabinet Dimensions (L x W x H) |

15.5″ x 13″ x 16.5″ | 22.5″ x 20″ x 19.5″ | 22.5″ x 20″ x 21.75″ |

| Arm Dimensions | 4″ or 5″ diameter 68″ long |

6″ diameter 72″ long |

|

| Cabinet Material | 316 stainless steel | ||

| Air Volume (approximately) |

Up to 350 CFM | Up to 700 CFM | Up to 877 CFM |

| Electrical | 115/1/60, 2 amps 220/1/50, 0.75 amp |

115/1/60, 2.5 amps 220/1/50, 1.5 amp |

115/1/60, 5.2 amps |

| Sound Level | 61 – 66 dba | 60 dba | 71 dba |

| Included Features | Variable Speed Controller, Portability Handle, Heavy-duty casters, and quick “no tool” filter change. | ||

| Optional Features | Magnehelic Gauge and hour counter | ||

| Web Link | Learn More about the Model 300 | Learn More about the Model 400/450 | |

| Brochure | Download the Model 300 Brochure | Download the Model 400/450 Brochure | |

Stainless Steel Ductless Fume Hood

The Stainless Steel Ductless Fume Hood provides an enclosure to separate the fume or particulate-producing process from the workspace. These systems contain the particulate or fume and draw them into the filtration system away from the operator’s breathing zone. After processing, the filtered air is released back into the surrounding room creating a recirculating airflow.

Technical Specifications

|

|

|

|

| Model/Part Number | 30″ Wide SS-330-DCH-ST |

40″ Wide SS-340-DCH-ST |

50″ Wide SS-350-DCH-ST |

| Hood Dimensions (L x W x H) |

Outer: 24″ x 32″ x 41.5″ Interior: 23.5″ x 30″ x 24″ Access Area: 8″ x 30″ |

Outer: 24″ x 42″ x 41.5″ Interior: 23.5″ x 40″ x 24″ Access Area: 8″ x 40″ |

Outer: 24″ x 52″ x 41.5″ Interior: 23.5″ x 50″ x 24″ Access Area: 8″ x 50″ |

| Hood Material | Hood: 16 awg 304 stainless steel Fasteners: 304 stainless steel Front Window: 0.25”clear polycarbonate |

||

| Blower Dimensions (L x W x H) |

15.5″ L x 13″ W x 14.5″ H | ||

| Blower Material | 16 Ga. carbon steel with polyester epoxy coating on all surfaces | ||

| Air Volume Approximately |

Up to 350 CFM | ||

| Inlet Velocities | Carbon Pre-filter + HEPA Filter – 130 FPM high, 25 FPM low | Carbon Pre-filter + HEPA Filter – 130 FPM high, 25 FPM low | Carbon Pre-filter + HEPA Filter – 105 FPM high, 25 FPM low |

| Electrical | 115/1/160, 2 amps 220/1/50, 0.75 amps |

||

| Sound Level | 61 to 66 dba (low to high) | ||

| Included Features | Variable Speed Controller (115V only), velometer, and LED light | ||

| Optional Features | Clear anti-static vinyl curtains, Magnehelic Gauge, hour counter, and spill tray | ||

| Web Link | Learn more about Stainless Steel Ductless Fume Hoods | ||

Improve indoor air quality in your food processing facility with Sentry Air’s Stainless Steel Fume Extractor! Call us today – 1-800-799-4609

Related Blogs

• Respiratory Hazards of Diacetyl and 2,3-pentanedione Exposure in the Coffee Roasting Industry

• Testimonial: Oil Mist Collector in Food Manufacturing Process

• Testing dairy products requires acid gas filter for fume extraction

References

Carter, C. (2023, Sept.). Complete Guide to Selection of Food Grade Stainless Steel for the Food Processing Industry. Metalphoto of Cincinnati. Retrieved from: https://www. mpofcinci.com/blog/food-grade-stainless-steel-for-food-processing-industry/.

FDA. (2017, Dec.). Full Text of the Food Safety Modernization Act (FSMA). FDA U.S. Food & Drug Administration Retrieved from: https://www.fda.gov/food/food-safety-modernization-act-fsma/full-text-food-safety-modernization-act-fsma.

Md Zamri, A. S. S., Saruddin, M. Z., Harun, A., Abd Aziz, S. F., Aizad Za’bah, A. K., Dapari, R., Hassan, M. R., Che Dom, N., & Syed Abdul Rahim, S. S. (2023). Factors associated with occupational asthma among food industry workers: A systematic review. PloS one, 18(6), e0287040. Retrieved from: https://doi.org/10.1371/journal.pone.0287040.

Piab. (2021, Nov.). Respiratory Hazards in the Food Industry and How to Eliminate Them. Piab. Retrieved from: https://www.piab.com/en-us/news/respiratory-hazards-and-how-to-eliminate-them.

WHO. (2024). Foodborne Illnesses. World Health Organization. Retrieved from: https://www.who.int/health-topics/foodborne-diseases#tab=tab_1.

Made in the USA

Made in the USA