Updated May 3, 2024

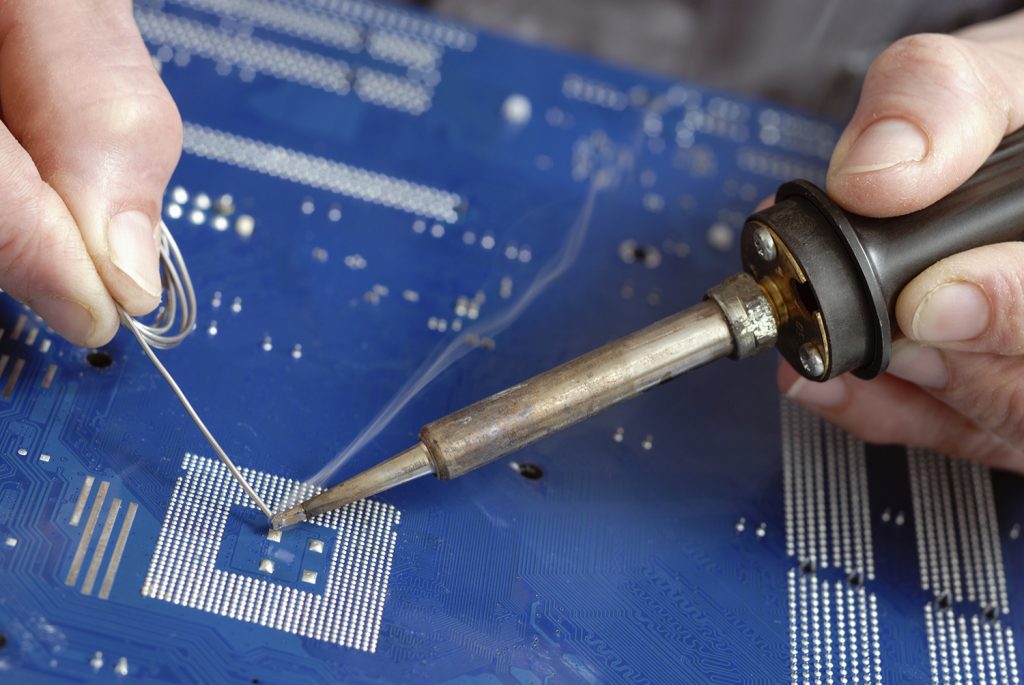

Soldering is a process in which heat is used to join two metals together by melting a third metal or solder. This process can produce fumes or solder smoke that can be hazardous to the operator. Depending on the application and particular solder, there is a wide variety of health concerns that can be associated with respirable solder fumes.

Soldering applications include (Deziel 2018):

• Fixing and manufacturing electronics including circuit boards

• Crafting jewelry, metalwork, and stained glass

• Building professions such as roofers, plumbers, gutter repairmen, and electricians

What are solder fumes (smoke)?

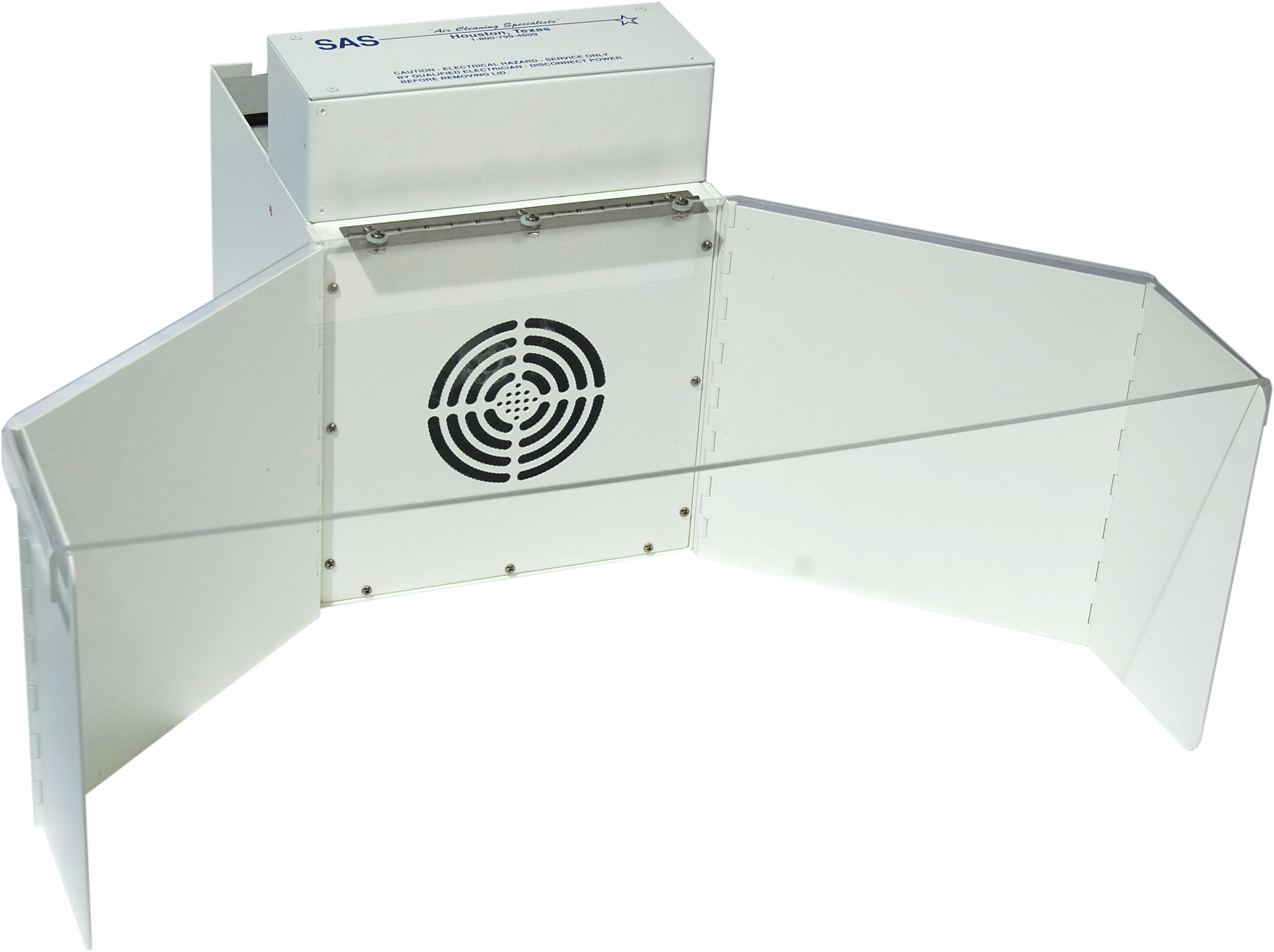

Benchtop Fume Extractor (SS-100-SS-ST) draws fumes away from the operator into the filtration system.

Solder fumes are composed of metal vapors from the solder and gas from the evaporated solder flux (Mraz 2015). Soldering melts metal alloys with low melting points to create a bond releasing metal vapors into the air. When using a solder flux, the soldering iron heats the solder flux to aid in the bond formation turning the solder flux into the gaseous state. This combination of exposure to solder vapors and gases can cause the operator lasting health effects depending on the type of solder and the solder flux, as well as the duration and frequency of the application.

Soldering Fumes Health Effects

Exposure to soldering fumes health effects mainly depends on the type of solder and the solder flux chemical composition. The most popular solders used contain lead, rosin, or are lead-free composed of tin, silver, and copper (Burris 2019). Other specialized solders include alloys of beryllium, aluminum, gold, iron, and brass. Overall, exposure to solder fumes can lead to the development of occupational asthma directly caused from work environment exposure (Mayo Clinic 2018). The operator may become sensitized to toxic and irritating substances leading to the development or worsening of asthma after exposure. Symptoms include chest tightness, wheezing, and shortness of breath. In particular, certain alloys of solders, such as lead-based solder and beryllium based solder, provoke more severe and long-lasting health effects than others, such as tin, silver, and gold. The health hazards for common solder components are detailed below:

Lead – May cause lead poisoning, kidney disease, hypertension, and weight loss. Targets the gastrointestinal tract, nervous system, kidneys, and blood (NIOSH Lead). Symptoms include metallic taste in the mouth, nausea, vomiting, headache, cramps, nervousness, and insomnia.

Tin – Considered relatively harmless but may generate benign pneumoconiosis, or eye, skin, and respiratory system irritation (NIOSH Tin).

Silver – May create throat irritation, blue gray eyes, nasal septum irritation, and gastrointestinal disturbance (NIOSH Silver).

Copper – Can produce eye and upper respiratory irritation, and metal fume fever (NIOSH Copper). Metal fume fever symptoms include fever, chills, aches, pains, nausea, and dizziness.

Beryllium – Classified as a Group 1 carcinogen. Can lead to beryllium sensitization possibly causing chronic beryllium disease with symptoms of shortness of breath, coughing, fatigue, night sweats, and fever. Can worsen over time forming granulomas or masses of immune cells on the lungs (OSHA Beryllium).

Aluminum – May provoke irritation to eyes, skin, respiratory system (NIOSH Aluminum).

Gold – Regarded as generally harmless but exercise caution with certain alloys (NIOSH Silver).

Iron – May lead to siderosis a form of pneumoconiosis (NIOSH Iron).

Brass (Zinc Oxide) – Can cause metal fume fever (NIOSH Zinc Oxide).

In addition to the exposure to solder fumes, solder fluxes containing fluoride and rosin based solder fluxes fumes can provoke lasting health symptoms. Inhalation of fluoride should be monitored due to the toxic nature of hydrogen fluoride and boron trifluoride. Both substances can cause eye, skin, nose, and throat irritation. Hydrogen fluoride exposure may cause pneumonitis, while boron trifluoride can lead to bronchitis and pulmonary edema due to the excess of fluid in the lungs (NIOSH Hydrogen Fluoride & Boron Trifluoride).

Rosin core solders and rosin based solder fluxes contain rosin which comes from the resins of pine trees. When heated, rosin creates a flux fume called colophony containing a complex mix of particulate and gases (University of Cambridge). The colophony particulates deposit deep within the lungs leading to lung damage and the possible development of occupational asthma (University of Cambridge). The colophony gases include acetone, methyl alcohol, methane, ethane, CO, and CO2 and aliphatic aldehydes with exposure causing upper respiratory irritations and possible formation of cancer (NIOSH Rosin Core Solder).

Soldering Safety OSHA

Soldering Workstation complete with two models of Soldering Fume Extractors

To safeguard employee health, OSHA requires employers to monitor air quality and restrict exposure to below mandated standards. OSHA legally enforces the permissible exposure limit (PEL) to help provide safe working environments. OSHA recommends employers to use ventilation or fume extraction systems at the source to restrict exposure to harmful soldering fumes. Although not legally enforced, NIOSH sets a recommended exposure limit (REL) based on all scientific study data available for the substance. The following chart summarizes the OSHA PELs and the NIOSH RELs for soldering and solder flux fumes contaminants (OSHA PEL).

Government Regulations of Common Soldering Substances (OSHA PEL)

| Substance | OSHA PEL | NIOSH REL |

| Aluminum (respirable) | 5 mg/m3 | 5 mg/m3 |

| Beryllium | 0.2 µg/m3 (0.0002 mg/m3) |

0.2 µg/m3 (0.0002 mg/m3) |

| Boron trifluoride | 1 ppm | 1 ppm |

| Copper (fume) | 0.1 mg/m3 | 0.1 mg/m3 |

| Hydrogen fluoride | 3 ppm | 3 ppm |

| Iron oxide (fume) | 10 mg/m3 | 5 mg/m3 |

| Lead | 0.05 mg/m3 | 0.05 mg/m3 |

| Rosin core solder (formaldehyde) |

0.1 mg/m3 | 0.1 mg/m3 |

| Silver | 0.01 mg/m3 | 0.01 mg/m3 |

| Zinc oxide | 5 mg/m3 | 5 mg/m3 |

Your Rights as an Employee

As an employee, you have the right to a safe breathing work environment. The OSHA Safety and Health Act of 1970 places responsibility on employers to provide a safe working environment free from harms likely or known to cause lasting health effects (OSHA). This responsibility includes substances without a permissible exposure limit. Employees have the right to proper ventilation in order to maintain optimal respiratory health and safety.

Soldering PPE Requirements

Operator soldering with proper PPE including safety glasses, gloves, and Winged Sentry Solder Fume Extractor

In addition to proper ventilation, employees must wear proper PPE to protect from other soldering hazards. Protective clothing, such as a long-sleeved shirt, pants, and gloves, prevents burns from splashes of hot solder. Protective eyewear, such as safety glasses or goggles, protects the eyes while soldering and clipping wires (Oregon State University).

Soldering Safety PPT

The powerpoint below showcases the information displayed in this blog. Download for easy reference.

Solder Fume Extraction Solutions

Sentry Air Systems offers a wide variety of solder fume extraction systems including benchtop, portable, and wall mounted units. These systems use ductless technology filtering out particulate and fumes with high quality filtration options. For filtering particulate filter options include HEPA (up to 99.97% efficiency on particles down to 0.3 microns), ULPA (up to 99.9995% efficiency on particles down to 0.12 microns), ASHRAE (up to 95% efficiency on particles down to 0.5 microns). For applications that need chemical fume extraction, we offer activated carbon filters or specialty blended filter media (acid gas, ammonia, aldehyde, and mercury). Select units allow for dual filtration options enabling the removal of chemical fumes as well as particulate. Ductless systems enable simple installation without the requirement for makeup air production or expensive ductwork. Flame retardant filter media provides an added safety benefit for heat-based solder fume extraction systems.

ESD-Safe Stainless Steel Benchtop Soldering Fume Extractor – (SS-100-SS-ST)

Winged Sentry Soldering Fume Extractor – (SS-200-WSL)

ESD-Safe Stainless Steel Floor Soldering Fume Extractor – (SS-100-FS-ST)

Wall Mounted Soldering Fume Extractor – (SS-200-SKY)

Contact us today to help protect employees from harmful soldering fumes with simple fume extraction solutions!

Call us today at 1-800-799-4609

References

Burris, Matthew. “Types of Solder.” Lifewire, 13 November 2019. https://www.lifewire.com/types-of-solder-flux-818849.

Deziel, Chris. “10 Different Uses for a Soldering Iron.” Hunker, 8 September 2018. https://www.hunker.com/13402927/10-different-uses-for-a-soldering-iron.

“Occupational Asthma.” Mayo Clinic, 22 May 2018. https://www.mayoclinic.org/diseases-conditions/occupational-asthma/symptoms-causes/syc-20375772.

Mraz, Stephen. “What’s the Difference Between Soldering, Brazing and Welding.” Machine Design, 14 July 2015. https://www.machinedesign.com/fasteners/whats-difference-between-soldering-brazing-and-welding.

NIOSH Pocket Guide to Chemical Hazards. “Aluminum.” 4 October 2019. https://www.cdc.gov/niosh/npg/npgd0022.html.

NIOSH Pocket Guide to Chemical Hazards. “Boron Trifluoride.” 4 October 2019. https://www.cdc.gov/niosh/npg/npgd0062.html.

NIOSH Pocket Guide to Chemical Hazards. “Copper.” 4 October 2019. https://www.cdc.gov/niosh/npg/npgd0150.html.

NIOSH Pocket Guide to Chemical Hazards. “Hydrogen Fluoride.” 4 October 2019. https://www.cdc.gov/niosh/npg/npgd0334.html.

NIOSH Pocket Guide to Chemical Hazards. “Iron Oxide Dust and Fume.” 4 October 2019. https://www.cdc.gov/niosh/npg/npgd0344.html.

NIOSH Pocket Guide to Chemical Hazards. “Lead.” 4 October 2019. https://www.cdc.gov/niosh/npg/npgd0368.html.

NIOSH Pocket Guide to Chemical Hazards. “Rosin core solder, pyrolysis products (as formaldehyde),” 4 October 2019. https://www.cdc.gov/niosh/npg/npgd0547.html

NIOSH Pocket Guide to Chemical Hazards. “Silver.” 4 October 2019. https://www.cdc.gov/niosh/npg/npgd0557.html.

NIOSH Pocket Guide to Chemical Hazards. “Tin.” 4 October 2019. https://www.cdc.gov/niosh/npg/npgd0613.html.

NIOSH Pocket Guide to Chemical Hazards. “Zinc Oxide.” 4 October 2019. https://www.cdc.gov/niosh/npg/npgd0675.html.

Occupational Safety and Health Administration. “Health Effects: Beryllium.” https://www.osha.gov/SLTC/beryllium/healtheffects.html.

Occupational Safety and Health Administration. “OSHA Annotated Table Z-1.”

https://www.osha.gov/dsg/annotated-pels/tablez-1.html.

Occupational Safety & Health Administration, “Occupational Safety and Health Act of 1970.” http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=OSHACT&p_id=2743.

Oregon State University. “Safety Instruction – Soldering Safety.” January 2017. https://ehs.oregonstate.edu/sites/ehs.oregonstate.edu/files/pdf/si/soldering_safety_si.pdf.

University of Cambridge. “Soldering Safety.” Department of Engineering Health & Safety. https://safety.eng.cam.ac.uk/safe-working/copy_of_soldering-safety.

Made in the USA

Made in the USA