What is Epoxy?

Epoxy, also known as polyepoxide or an epoxy resin system, is the combination of epoxy resin and a curing agent (also called a catalyst or hardener). Common applications include bonding adhesive, paints and coatings, primers and sealers, patching and resurfacing, flooring, chemical containment, wood repairs, electrical applications, composite materials, marine applications, aerospace applications, art, and numerous other uses.

Cured epoxy poses few health risks (note: sanding cured epoxy will produce dust, which should not be inhaled); however, liquid and partially cured epoxies introduce numerous health threats that need to be managed as efficiently as possible with preventative measures.

Epoxy Health Risks

When liquid epoxy evaporates, (this evaporation process speeds up with poor ventilation and high temperatures) its fumes become respirable. Other respirable particles are produced by sanding partially cured epoxy. Epoxy may be hard enough to sand after a couple of hours, however it may not be completely cured for up to two weeks. The dust produced by the sanding of this epoxy contains hazardous components. [Ref. 1 & 4]

Epoxy Exposure Respiratory Harm

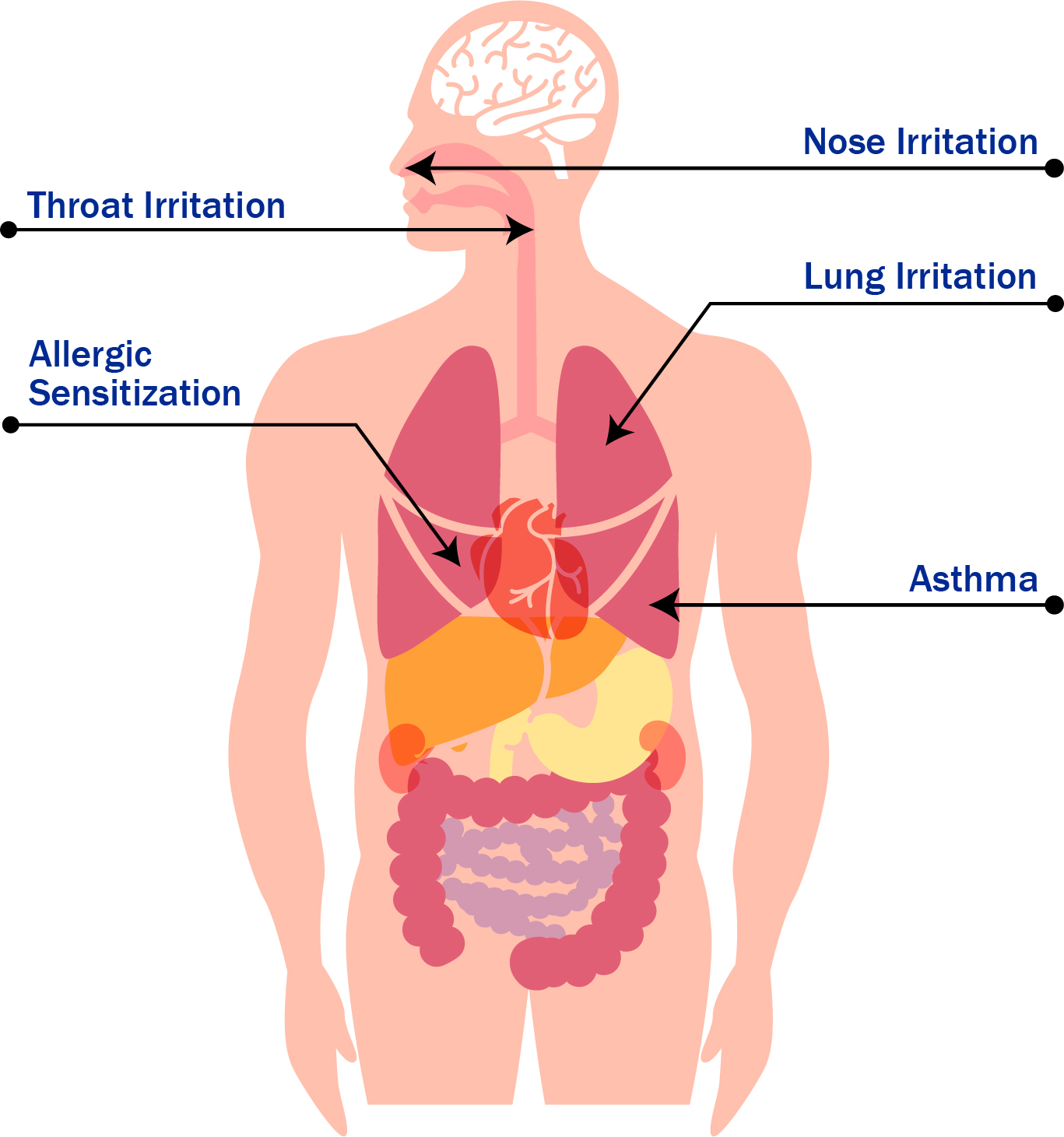

When epoxy fumes are inhaled, they can affect the nose, throat, and lungs. Most symptoms from the inhalation of epoxy involve inflammation and therefore irritation of the nose, throat, and lungs. Repetitive and high amounts of exposure to these fumes can result in sensitization and asthma.

When the dust from partially cured epoxy is inhaled, the particles become trapped in the mucus lining of the respiratory system and can cause serious health problems. According to West System, a leading epoxy manufacturer, this dust should never be inhaled. [Ref. 2]

Epoxy Sensitization and Asthma

Sensitization, in this case, is the state of being allergic to epoxy. Sensitization can occur at any point, regardless of how many times or for how long you’ve been exposed to epoxy. Your chances of being sensitized will increase if you’re exposed to a greater amount of fumes in an unventilated area, but even one episode of exposure can lead to an allergic reaction. This is why preventative safety is so important in regard to epoxy. Once sensitized, even small amounts of the substance can trigger allergic reactions and it will be increasingly difficult to work with the material. There is also no definite cure for sensitization, only methods to relieve the symptoms. [Ref. 2]

According to MayoClinic.com, sensitization from irritant exposure in the workplace can be classified as Occupational Asthma, which is defined as “asthma that’s caused or worsened by breathing in a workplace irritant, such as chemical fumes, gases or dust. Like other types of asthma, occupational asthma can cause symptoms, such as chest tightness, wheezing and shortness of breath” [Ref. 3]. Also according to MayoClinic.com, two of the “High-Risk Occupations” for developing occupational asthma are Adhesive Handlers and Users of Plastics and Epoxy Resins, among many others. [Ref. 3]

For further information on Occupational Asthma: OSHA or Mayo Clinic

Epoxy Fume Control Solutions

One effective step you can take to help protect yourself from epoxy fumes is establishing a proper ventilation system.

Ductless Fume Hoods

Ductless Fume Hoods [Model SS-340-DCH pictured left] provide an enclosed environment that pulls harmful fumes up and away from the operator through a fan/filtration system that utilizes activated carbon filtration and ultimately disperses filtered air back in the room. The activated carbon filters are able to adsorb the chemical fumes from epoxy, creating a safe working environment for the operator. Specialty filter media is available depending on the chemical composition of the epoxy being used.

Ductless Fume Hoods [Model SS-340-DCH pictured left] provide an enclosed environment that pulls harmful fumes up and away from the operator through a fan/filtration system that utilizes activated carbon filtration and ultimately disperses filtered air back in the room. The activated carbon filters are able to adsorb the chemical fumes from epoxy, creating a safe working environment for the operator. Specialty filter media is available depending on the chemical composition of the epoxy being used.

Portable Fume Extractors

The Portable Floor Sentry [Model SS-300-PFS pictured left] is equipped with a self-supporting flex arm so the operator can place the source capture area where it’s needed the most. This compact system allows the operator the ability to source capture the epoxy fumes in confined spaces.

The above units are all equipped with Activated Carbon filtration. Specialty filter media is available depending on the chemical composition. In order to choose the correct unit for your unique application, one of our Applications Specialists will review the Material Safety Data Sheet (MSDS) with you and determine the proper ventilation system. There are numerous options beyond the units listed above.

Contact us today to find your best suited solution to control epoxy fumes!

Call us at 1.800.799.4609

Sentry Air Systems, Inc. provides this information as a customer service, but cannot be responsible for its accuracy or completeness. It is recommended that competent legal authorities as well as safety and hygiene professionals be consulted.

References

[1] WestSystem.com, “Understanding Overexposure”: https://www.westsystem.com/safety/understanding-overexposure/

[2] WestSystem.com, “Health Effects from Overexposure to Epoxy”: https://www.westsystem.com/safety/health-effects-from-overexposure-to-epoxy/

[3] MayoClinic.com, “Occupational Asthma”:

http://www.mayoclinic.com/health/occupational-asthma/DS00591

[4] California Department of Public Health, “Epoxy Resin Systems”:https://www.cdph.ca.gov/Programs/CCDPHP/DEODC/OHB/HESIS/CDPH%20Document%20Library/epoxy.pdf

[5] United States Occupational Safety and Health Administration (OSHA), “Occupational Asthma”:http://www.osha.gov/SLTC/occupationalasthma/index.html

Made in the USA

Made in the USA