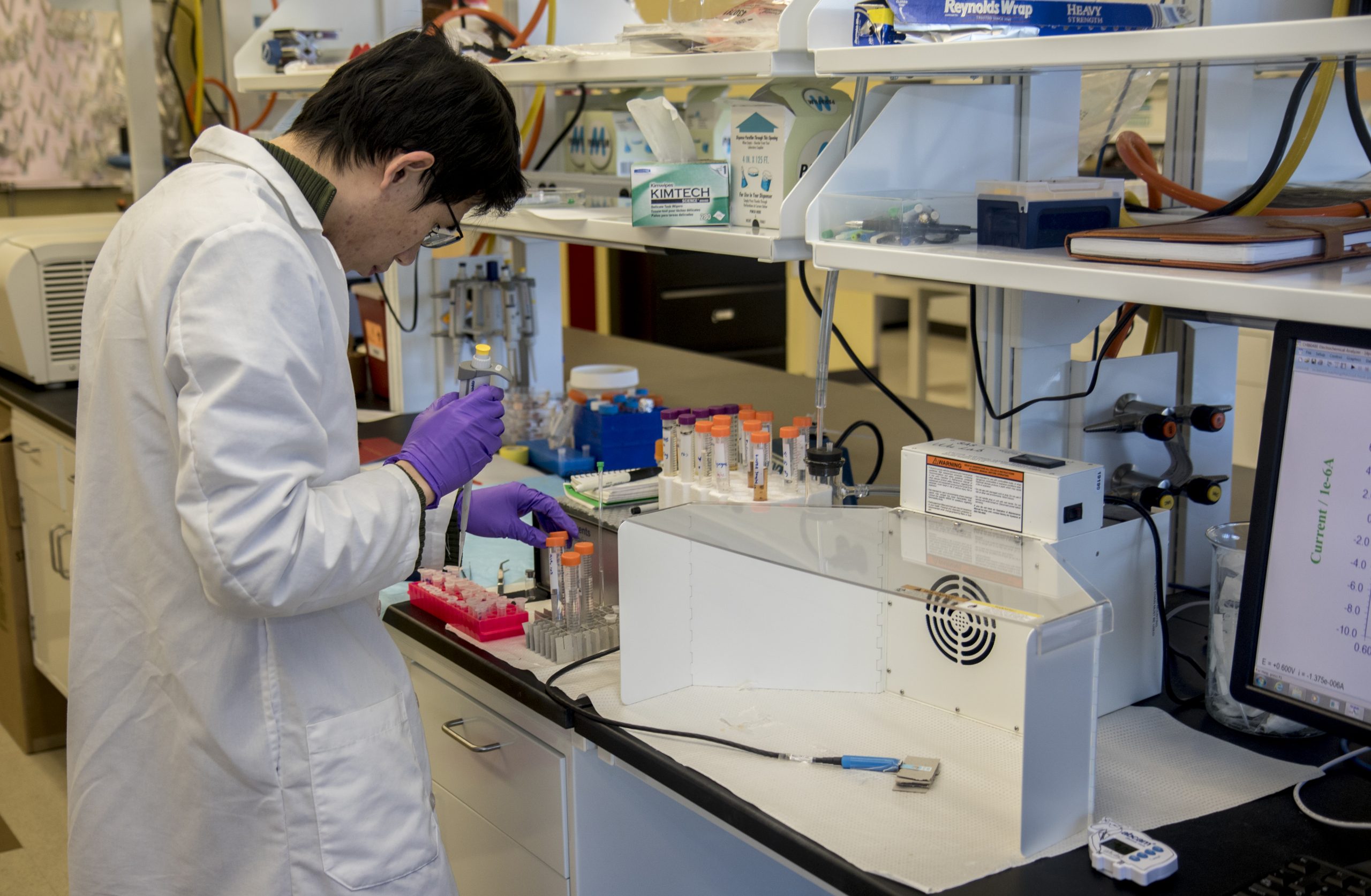

Engineering Controls, such as Ductless Fume Hoods, help protect the operator from inhaling harmful solvent fumes like TCE and PCE.

Recently, the US Environmental Protection Agency (EPA) announced the ban and phase-out plan for solvents trichloroethylene (TCE) and perchloroethylene (PCE). These restrictions are completed under amendments to the 2016 Toxic Substances Control Act (TSCA). The EPA’s press release details TCE and PCE risk management rules including the plans to ban both solvents, exempt industries, and exposure controls to reduce exposure (EPA 2024a). These solvents will be banned for most uses with an extended phaseout and/or exemption for certain industrial uses (EPA 2024a). The EPA is banning these solvents to help prevent cancer development in people working with these chemicals or living nearby. TCE & PCE exhibit carcinogenic properties that can cause harmful side effects from even a small amount of exposure. Exempted industries must adopt a Workplace Chemical Protection Plan using engineering controls such as fume extractors to help reduce operator exposure (EPA 2024a).

What is the 2016 Toxic Substances Control Act (TSCA)?

The new amendment to the Toxic Substances Control Act enables the EPA to assess and set safety health standards for harmful chemicals.

What is Trichloroethylene (TCE)?

Trichloroethylene (TCE) is found in many common products such as brake cleaners, degreasers, and more.

What is Perchloroethylene (PCE)?

Perchloroethylene (PCE) is used in products for dry cleaning, refrigerants, and more.

New EPA Regulations

TCE Regulations

The EPA is banning TCE within 1 year for most commercial and all consumer products but allowing a longer phaseout period for certain applications critical to infrastructure or national defense security (EPA 2024b). EPA has set this low exposure limit due to the harmful side effects from a small amount of exposure. All applications with a longer phaseout will eventually be banned except for a 50-year exemption for laboratory uses (EPA 2024c). Industrial applications that will have a longer phaseout include (EPA 2024c):

• Cleaning aircraft/medical devices

• Manufacturing battery separators and refrigerants

• Transportation

• Security and defense systems

• National security/critical infrastructure

• Laboratory uses for TCE disposal in wastewater

Workplaces that will be allowed to use TCE must implement a Workplace Chemical Protection Plan that includes exposure controls to meet the new exposure limit of 1.07 mg/m3 (0.2 ppm) (EPA 2024b). The new exposure limit is a big reduction from the previous OSHA PEL (100 ppm) and NIOSH REL (2 ppm). The EPA requires businesses to implement an exposure control plan by December 18, 2025 (EPA 2024c).

PCE Regulations

EPA’s risk management program for PCE includes rapidly reducing manufacturing, processing, and distribution (EPA 2024a). Most uses will be phased out within 3 years. Dry cleaning facilities will have a 10-year phaseout for older machines and 6 months for new machines. Highly specialized applications will be required to implement a Chemical Protection Plan including exposure controls to meet the new exposure limit of 0.98 mg/m3 (0.14 ppm) (EPA 2024b). Applicable exempt workplaces will have 30 months to implement exposure controls (EPA 2024d). The current OSHA PEL is much higher (100 ppm) than the new EPA exposure limit of 0.14 ppm. After hearing public comments, the EPA is allowing extra time for workplaces to implement workplace safety controls due to this drastic reduction in the exposure limit (EPA 2024d). Applications with an extended phaseout are mostly for government purposes related to national security, aviation, critical infrastructure, and EPA purposes for reducing climate change (EPA 2024d).

Exposure Controls for TCE and PCE Chemical Protection Plans

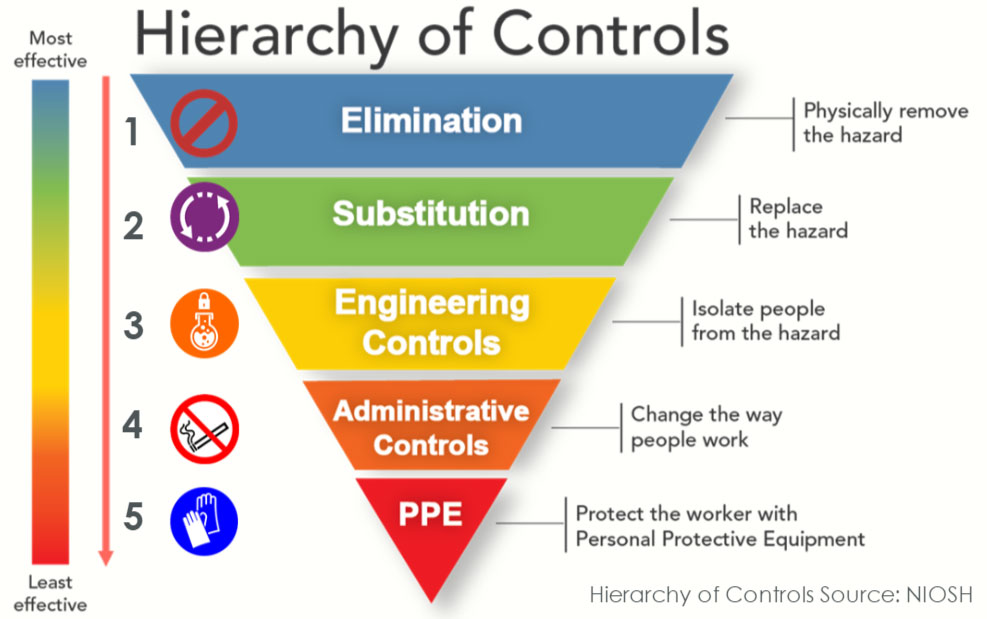

Hierarchy of Controls shows the priority of exposure controls to help reduce solvent fume exposure.

*Not guaranteed. Average figure. Please consult the factory for more information.

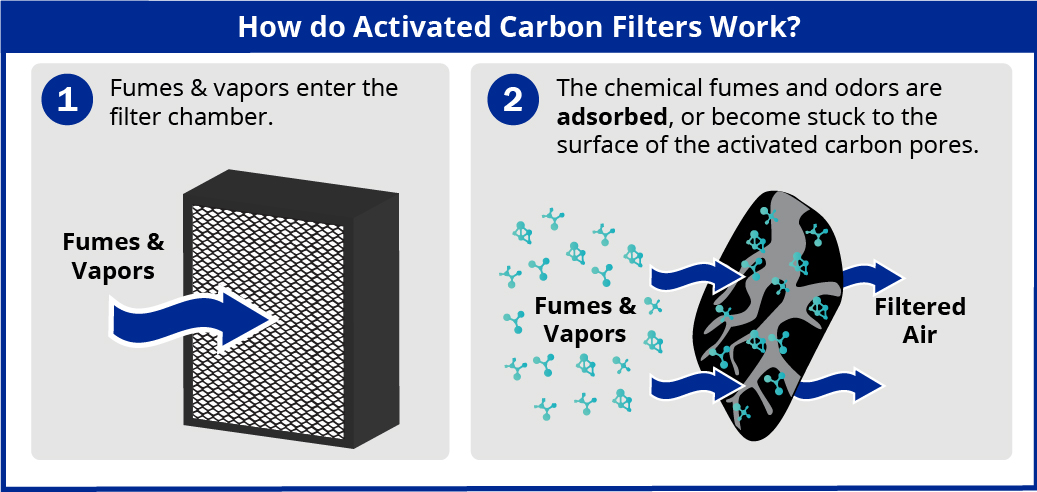

How do Activated Carbon Filters work?

This graphic depicts how Activated Carbon filters adsorb chemical fumes.

Activated Carbon Filters work through a process called adsorption. Adsorption occurs when airborne contaminants pass over carbon granules and stick to the surface removing them from the airflow. Activated Carbon is treated to increase the porosity and surface area improving the overall removal efficiency. Activated Carbon filters are ideal for the removal of airborne odors and fumes.

Benefits of Sentry Air Systems’ Activated Carbon Filters

Only high-quality Activated Carbon granules are used to create Sentry Air Systems Activated Carbon filters.

• Stringent product testing

• Custom-made Activated Carbon filters available

• Made in the USA

• Free chemical assessment from on-staff chemical engineer

• Responsive and knowledgeable customer service

TCE and PCE Solvent Fume Engineering Controls

Sentry Air offers a variety of engineering controls in different configurations suited for workplaces of all sizes. Depending on your application and workspace layout, we offer a solution that will provide long-lasting and reliable solvent fume control. Our systems offer low maintenance mainly requiring a filter change as needed.

Industrial Applications Solutions

Portable Fume Extractors

Portable Fume Extractors capture fumes at the source preventing them from reaching the operator’s breathing zone.

Benefits:

• Portable

• Self-supportive fire-retardant flex arm

• 360° swivel

• Small footprint

• Easy filter change

Technical Specifications:

*Airflow will vary when using Activated Carbon filters.

Heavy-Duty Industrial Fume Extractors

Heavy-duty Industrial Fume Extractors feature a heavy-duty extractor arm and provides more airflow.

Benefits:

• (4) 42 lb Activated Carbon Filters for higher concentrations of chemical fumes (168 lbs total)

• 7′ or 10′ long heavy-duty arm

• Heavy-duty casters and handle

• Low maintenance

Technical Specifications:

**Actual CFM with Activated Carbon Filters

Laboratory Applications Solutions

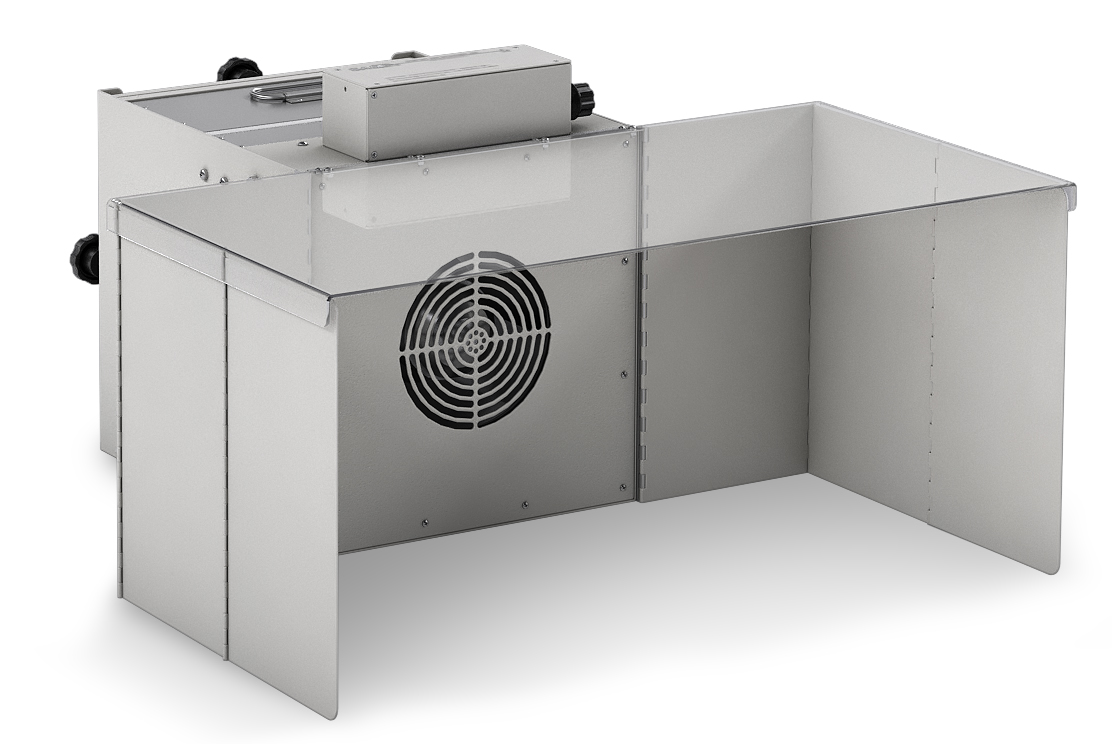

Ductless Fume Hoods

Ductless Fume Hoods create an enclosure that helps protect the operator from inhaling harmful solvent fumes. (24” shown)

Benefits:

• Economical and versatile solution for a variety of laboratory applications

• Lightweight and portable

• Ductless design – no expensive ductwork or makeup air

• Includes variable speed controller and LED light for most models

• Wide variety of standard sizes: 12”, 18”, 24”, 30”, 40”, 50”, 60”, and 70”

• Standard sizes ship within 5 business days

• Custom construction and sizes available

• Low maintenance – only need to change the filter!

• Back by a limited 2-year warranty

• Made in the USA

Technical Specifications:

| Construction | Side | 0.25” white acrylic |

| Base | 0.5” high-density polyethylene | |

| Top | 0.5” clear polycarbonate | |

| Window | 0.25” clear polycarbonate | |

| Air Volume | 12″, 18″, 24″ (Model 200) | Up to 80 CFM* |

| 24″, 30″, 40″, 50″, 60″, 70″ | Up to 350 CFM* | |

| Inlet Velocities | 12″ & 18″ | 60 FPM |

| 24″ (Model 200) | 40 FPM | |

| 24″ (Model 300) | 60 FPM | |

| 30″ & 40″ | 115 FPM | |

| 50″ | 80 FPM | |

| 60″ & 70″ | 70 FPM | |

| Electrical | Model 200 | 115/1/60, 0.3 amps 220/1/50, 0.2 amps |

| Model 300 | 115/1/60, 2 amps 220/1/50, 0.75 amps |

|

| Sound | Model 200 | 55 dba |

| Model 300 | 61 – 66 dba | |

| Max Temperature | Not to exceed 170° F (76° C) | |

*Airflow will vary with Activated Carbon Filters.

Benchtop Fume Extractors

Benchtop Fume Extractors provide solvent fume control for workspaces that can’t fit a traditional hood.

Benefits:

• Reliable

• Low maintenance

• Small footprint

• Adjustable wing flaps and acrylic lid create a hood-like enclosure

Technical Specifications:

|

|

|

| Model | Model 200* | Model 300 |

| Construction | 16 ga carbon steel 1/8” clear acrylic lid |

|

| Air Volume | Up to 50 CFM (carbon) | Up to 350 CFM** |

| Electrical | 115/1/60, 0.3 amps 220/1/50, 0.2 amps |

115/1/60, 2 amps 220/1/50, 0.75 amps |

| Sound | 56 dba | 61 – 66 dba |

*For use with small applications with low concentrations only. Higher concentrations recommended to use Model 300.

**Airflow will vary with Activated Carbon filters

Contact us today to get started on selecting engineering controls to help reduce TCE and PCE solvent fume exposure in your workplace!

Call us at 1-800-799-1609

Related Blogs & Links

• Utilizing Specialty-Blended Activated Carbon Filters to Optimize Chemical Fume Adsorption – https://www.sentryair.com/blog/filters/specialty-blended-activated-carbon-filters/

• Reducing Exposure to Hazardous Organic Solvents – https://www.sentryair.com/blog/industry-applications/chemical-solvents/reducing-hazardous-exposure-to-organic-solvents/

• Testimonial: Ductless Spray Paint Booth for Paints & Solvents – https://www.sentryair.com/blog/testimonial/testimonial-ductless-spray-paint-booth-for-paints-solvents/

• Activated Carbon Adsorption Index Chart – https://www.sentryair.com/blog/wp-content/uploads/2025/01/SentryAirSystems-ActivatedCarbon-Adsorption.pdf

References

Agency for Toxic Substances and Disease Registry (ATSDR). (2020, June 22). Public Health Statement for Trichloroethylene (TCE). Toxic Substances Portal. Retrieved from: https://wwwn.cdc.gov/TSP/PHS/PHS.aspx?phsid=171&toxid=30.

ATSDR. (2019a, June). Tetrachloroethylene – ToxFAQs. Retrieved from: https://www.atsdr.cdc.gov/toxfaqs/tfacts18.pdf.

ATSDR. (2019b, June). Trichloroethylene – ToxFAQs. Retrieved from: https://www.atsdr.cdc.gov/toxfaqs/tfacts19.pdf.

EPA. (2024a, December 9). Biden-Harris Administration Announces Latest Actions under Nation’s Chemical Safety Law to Protect People from Cancer-Causing Chemicals Trichloroethylene and Perchloroethylene. United States Environmental Protection Agency. Retrieved from: https://www.epa.gov/newsreleases/biden-harris-administration-announces-latest-actions-under-nations-chemical-safety-law.

EPA. (2024b, December 18). List of Final and Proposed Existing Chemical Exposure Limits under TSCA. United States Environmental Protection Agency. Retrieved from: https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/list-final-and-proposed-existing-chemical-exposure.

EPA. (2024c, December 17). Trichloroethylene (TCE); Regulation Under the Toxic Substances Control Act (TSCA). Federal Register Vol. 89, No. 242. Retrieved from: https://www.govinfo.gov/content/pkg/FR-2024-12-17/pdf/2024-29274.pdf.

EPA. (2024d, December 18). Perchloroethylene (PCE); Regulation Under the Toxic Substances Control Act (TSCA). Federal Register/Vol. 89, No. 243. Retrieved from: https://www.govinfo.gov/content/pkg/FR-2024-12-18/pdf/2024-30117.pdf.

EPA. (2024e, May 28). Frequent Questions on the Frank R. Lautenberg Chemical Safety for the 21st Century Act. United States Environmental Protection Agency. Retrieved from: https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/frequent-questions-frank-r-lautenberg-chemical-safety#briefings.

Made in the USA

Made in the USA