Industrial Downdraft Table

Industrial Downdraft Tables, manufactured by Sentry Air Systems, are highly effective stainless steel source-capture solutions for the extraction of fume, dust, and smoke at the work surface level. This safety engineering control helps to protect the operator’s breathing zone and surrounding environment from hazardous airborne contaminants by creating negative pressure and pulling respirable particles into the filtration system.

Industrial Downdraft Table

Model # SS-XXX-XXX

Unit Configurations Quick Compare

What is an Industrial Downdraft Table?

An Industrial Downdraft Table is a source-capture workbench that pulls fumes, dust, and vapors down through the work surface, utilizing negative pressure, through an air filtration system in order to protect the operator’s breathing zone. “Industrial” downdraft tables offer a stable structure with powerful cfm to handle heavy-duty projects such as solvent vapor control, solder fumes, light grinding, epoxy fume control, sanding, and a variety of other industrial applications.

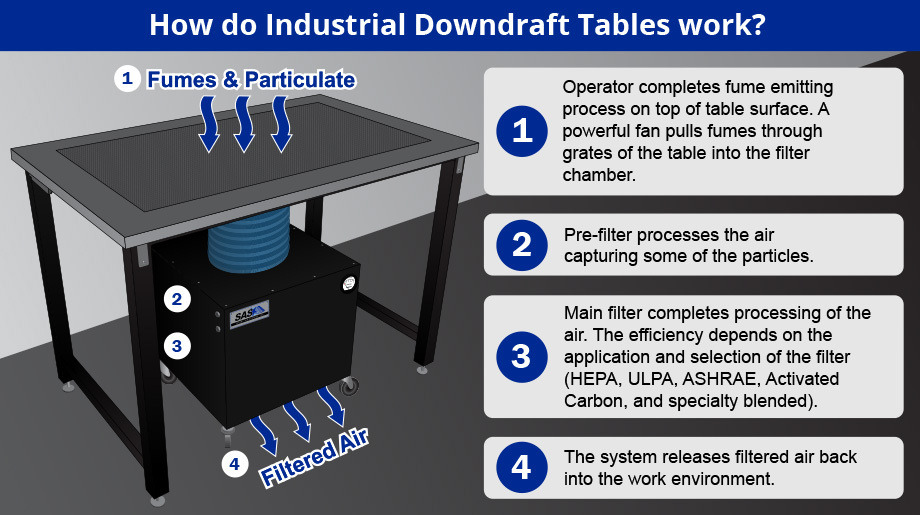

How do Industrial Downdraft Tables work?

Is your application appropriate for an Industrial Downdraft Table?

In most instances, applications that involve fume and vapor control, powder containment, or respirable material from grinding or sanding can use an industrial downdraft table as an engineering safety control.

However, some downdraft tables (if not adequately suitable or filtered) limit applications that can be performed on them due to high volatility and gases that cannot be filtered. In these circumstances, important considerations must be taken, including what types of chemicals will be handled, the quantity, and at what temperature. It is also important to note that this is not a wet application downdraft table and speaking with an application specialist is recommended to qualify if your process fits the capabilities of an industrial downdraft table.

Recommended applications for an Industrial Downdraft Table

- Solvent and Epoxy Fumes

- Welding

- Powder Containment

- Parts Cleaning

- Soldering

- Grinding (Light)

- Sanding

- Buffing

- Brazing

Benefits of an Industrial Downdraft Table

- Minimize employee exposure to contaminated air.

- Meet your legal obligations

- Heavy Duty Construction

- Low power consumption

- Reliable , low maintenance operation

- No permitting issues for venting outside (ie. EPA air sampling)

Industrial Downdraft Table

Product Video

Bench Dimensions:

- (48"W x 30"D x 35"H Featured)

Perforated Work Area:

- Stainless Steel ¼" Perforated Work Area

Cabinet Dimensions:

22.5" D x 20" W x 19.5" H

Total Weight:

Approx. 150 lbs.

Air Volume:

700 CFM High, Down to 50 CFM Low

Electrical:

115/1/60, 2.5 amps

220/1/50, 1.5 amps

Sound Level:

60 dba @ 3 ft. from hood inlet

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Quick Compare

Industrial Downdraft Table

|

|

|---|---|

| Cabinet Dimensions: | 22.5" D x 20" W x 19.5" H |

| Weight: | Approx. 150 lbs. |

| Electrical |

115/1/60, 2.5 amps 220/1/50, 1.5 amps |

| Sound Level | 60 dba @ 3 ft. from hood inlet |

Request A Quote or Contact Us

If you prefer, you may contact us by calling 800-799-4609, or e-mail us at sales@sentryair.com.

Name and Email are required.

Made in the USA

Made in the USA