Sentry Air Systems Filters

- Sentry Air Systems Filters

- HEPA Filters

- ASHRAE Filters

- ULPA Filters

- How do air filters work?

- Filter Efficiency

- MERV Ratings

Sentry Air Systems Filters

In order to filter out harmful particulates and carcinogenic fumes, fume extractors and air purification systems utilize HEPA, ASHRAE, and ULPA to remove these respirable pollutants from the air. Unlike typical filters, high efficiency air filters are made of a complex web of fibers composed of dense glass, and pleated, similar to an accordion, which increases the total surface area and creates lower resistance to air-flow. Due to the lower resistance, these filters are recommended for applications that require high efficiency to remove particulates with a size of less than 0.6 microns.

Air filters are typically standardized by governing boards (NIOSH, EPA, OSHA, etc.) and/or dependent of the application that it is utilized with. In most cases, HEPA | ASHRAE | ULPA filters are recommended in applications where extremely hazardous particles, fumes, and chemicals can pose a threat to the user and/or environment. These filters are rare in form as they become more efficient with the continued use of the air filtration system. This is due to impaction, a process in which particulate that are larger than the spaces between the fibers are trapped in the filter as the air flow is pulled, or pushed, through the system. As the particulates become embedded in the filter, the alloted airflow space between the fibers becomes more clogged, thus, making for a more efficient filter.

HEPA Filters

Higher Efficiency

High efficiency particulate air (HEPA) filters must meet the efficiency rating of 99.97%, on particles as small as 0.3 microns, set by the US Department of Energy in order to be a true HEPA filter5. Some HEPA filters marketed for consumers do not meet these standards and are not true HEPA filters with the same capability or efficiency. HEPA filters have a MERV rating of 17 and provide excellent filtration for bacteria, lung damaging dust, spores, pollen, pulverized coal, and metallurgical dust and fumes.

HEPA filters were first invented for use in World War II to capture radioactive particles released from an atomic bomb6. However, the certification standard was not implemented until 1983. Today, HEPA filters must undergo strict testing to ensure accurate efficiency rating and classification.

HEPA Filter Features

- 100% Fire Retardant

- Polyalphaolefin PAO Batch Tested* (a test gas with an equal mean distribution of .3 microns distrusted through an aerosol generator)

- Unabridged, gasket closed cell neoprene

- Multi-level quality assurance

- Hand crafted with specialty purpose fiberglass material

- Up to 99.97% efficiency on particles down to 0.3 microns in size.

- MERV 17

*not all series HEPA PAO tested/varies by machine and application

ASHRAE Filters

High Efficiency

An ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) filter refers to a fibrous filter that has efficiency up to 95% on particles as small as 0.5 microns. This type of filter is very similar to the HEPA filter but does not have as high of an efficiency rating. The MERV efficiency rating is 14 for this filter and can be used to capture bacteria, pollen, spores, and other harmful particulates.

ASHRAE Filter Features

- 100% Fire Retardant

- Polyalphaolefin PAO Batch Tested (a test gas with an equal mean distribution of .3 microns distrusted through an aerosol generator)

- Unabridged, gasket closed cell neoprene

- Multi-level quality assurance

- Hand crafted with specialty purpose fiberglass material

- Up to 95% efficiency on particles down to 0.5 microns in size.

- MERV 14

ULPA Filters

Highest Efficiency

Ultra low particulate air (ULPA) filters have efficiency of up to 99.9995% on particles as small as 0.12 microns. ULPA filters have a MERV rating of 20 and are the highest quality filters available. ULPA filters provide better filtration for tobacco smoke, oil smoke, insecticide dust, carbon dust, and even capture some viruses.

ULPA Filter Features

- 100% Fire Retardant

- Polyalphaolefin PAO Batch Tested* (a test gas with an equal mean distribution of .3 microns distrusted through an aerosol generator)

- Unabridged, gasket closed cell neoprene

- Multi-level quality assurance

- Hand crafted with specialty purpose fiberglass material

- Up to 99.9995% efficiency on particles down to 0.12 microns in size.

- MERV 20

*not all series HEPA PAO tested/varies by machine and application

How do air filters work?

HEPA | ASHRAE | ULPA filters capture particulate using four main methods: sieving, inertial impaction, interception, and diffusion3. The type of filtration method depends on the size of the particle.

Sieving

Sieving is when a large particle is trapped by a filter because it is too large to pass through the hole in between the filter fibers3. Sieving is a method that all filters use to capture particles1. Although, it is not the main method of filtration for HEPA filters, HEPA filters do still collect larger particles in this manner.

Inertial Impaction

Inertial impaction happens with larger particles that collide directly with the fibers of the filter4. Larger particles are unable to adjust quickly to the air stream due to inertia and continue along its original path directly into the fiber3. This happens more often with larger particles because more mass equals more inertia or resistance to change paths.

Interception

Interception occurs when a particle is following a gas streamline or path and comes within one particle radius away from the fiber and brushes up against it3. The fiber captures the particle and is removed from the gas flow.

Diffusion

Diffusion refers to the filtration method where smaller particles move in a zigzag or random path and ends up sticking to the filter fiber3. Diffusion occurs because of the Brownian theory of motion where gas particles constantly collide with each other moving in a random motion3. Diffusion primarily happens to particles smaller than 0.1 microns in size and with slower air flow3.

Filter Efficiency

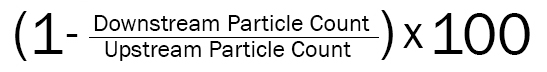

Efficiency of a filter is calculated by measuring the particle count downstream and upstream from the filter. The downstream count is divided by the upstream count then this number is subtracted from one then multiplied by 100 to create an efficiency percentage3.

Filter Efficiency Comparison Chart

|

Filter |

Efficiency and Particle Size |

|

ASHRAE |

Up to 95% on particles as small as 0.5 microns |

|

HEPA |

Up to 99.97% on particles as small as 0.3 microns |

|

ULPA |

Up to 99.9995% on particles as small as 0.12 microns |

Particle Size

To illustrate the miniscule size of particles that these filters capture, one micron is equal to one millionth of a meter. The human eye cannot see particles smaller than 10 microns. Sizes of common particles are as follows:

- Human hair: 100-150 microns in diameter

- Emissions 1 – 150 microns

- Dust: < 100 microns

- Pollen: 10 - 100 microns

- Spores: 3 - 40 microns

- Mold 3 - 12 microns

- Bacteria: 0.3 - 60 microns

- Pure oxygen 0.005 microns4.

MERV Ratings

MERV ratings refer to the minimum efficiency reporting value and helps classify filters. The chart below details different MERV ratings, efficiency and filters at that rating7.

| MERV Rating | Efficiency for Smaller Particles | Efficiency for Larger Particles | Particulates Best Used For | Filter Type |

| 1-4 | <20% | 65-80% | pollen, dust, sanding dust, bigger than 10 microns | residential A/C units, throwaway filters |

| 5-8 | 20-35% | 80-95% | mold spores, cement dust | better residential filters, commercial building filters, pleated filters for industrial settings |

| 9-12 | 40-75% | 90-95% | milled flour, welding fumes | better commercial building filters, hospital laboratories |

| 13-16 | 89->95% | >98% | bacteria, smoke | ASHRAE filters, hospital inpatient care, smokers lounges, general surgery areas |

| 17-19 | – | 99.97% | combustion smoke, pharmaceutical manufacturing, viruses or radioactive materials | HEPA filters |

| 20 | – | 99.995% | Clean rooms | ULPA filters |

Made in the USA

Made in the USA