Walk-In Fume Hoods

Walk-In Fume Hoods, manufactured by Sentry Air Systems, are designed to isolate a work process within a larger workspace so as to not cross contaminate between various applications. These enclosures are the ideal way to remove fumes, dust, vapors, and odors generated from oversized machinery or applications that are too large for benchtop fume extraction solutions. Also, these walk-in enclosures can be utilized to create a Walk-in Clean Room providing a reduced-particulate workspace.

Model # SS-XXX-XXX

Additional Configurations

What is a Walk-In Fume Hood?

Walk-In Fume Hoods are "oversized" enclosures that are built to seclude the exterior of the hood from fumes, dust, odors, and other particulate. Primarily, these hoods isolate the environment from particle contamination and allow applications to be performed in a separate working area. Also referred to as machine enclosures, these containment systems are used for a variety of applications including data recovery, tissue culture, drum and bin storage, botany, pharmaceutical, light grinding, sanding, and other applications that produce hazardous particulates and fumes.

Types of Walk-in Hoods

Sentry Air Systems offers 3 different kinds of Walk-in Enclosures to allow customers a solution suited for their needs.

Quick Ship Walk-in Fume Hood

Quick Ship Walk-in Fume Hoods provide an off-the-shelf oversized fume control solution that ships in 5 business days. Due to the in-stock availability, Quick Ship Walk-in Enclosures offer less options but still accommodate popular customer selections. Options available include:

- Size – 8’ W x 8’ D x 8’ H or 10’ W x 10’ D x 8’ H

- Wall Material – hard walls made of twinwall polycarbonate or anti-static vinyl curtains

- Ductless or Exhaust – available with up to 4 air cleaners or up to 4 exhaust collars

Custom Walk-in Fume Hood

Sentry Air Systems provides walk-in hoods in a variety of heights, depths and configurations. Customized walk-in enclosures can be up to 20’ wide, 20’ deep, and 9’ tall. At SAS, we recognize that work processes and space Quick Ship Custom Clean Room Quick Ship Walk-in Fume Hoodrequirements are unique, which is why our Walk-in Fume Enclosures are fully customizable. In addition to custom size dimensions, the modular design of our walk-in enclosures allows flexibility between ductless or ducted fume exhaust. Due to the custom nature of this product, typical lead time is 3-4 weeks after design approval. Additional custom options and accessories include:

- Floor Mounting

- Clear Anti-Static Vinyl Strip Curtains

- Floor Panel made of High-Density Polyethylene

- Multiple Filter Units

- Exhaust Collars for Ductwork

- Quick-change Pre-Filters

- Remote Control Operation

- Frame Paint Color

Custom Walk-in Clean Room Hood

Custom Walk-in Clean Rooms offer an easy-to-setup solution to create an oversized positive-pressure enclosure. These systems meet up to ISO Class 7* Clean Room standards and offer the same customization features as custom Walk-in Fume Hoods. (*efficiency may vary by size)

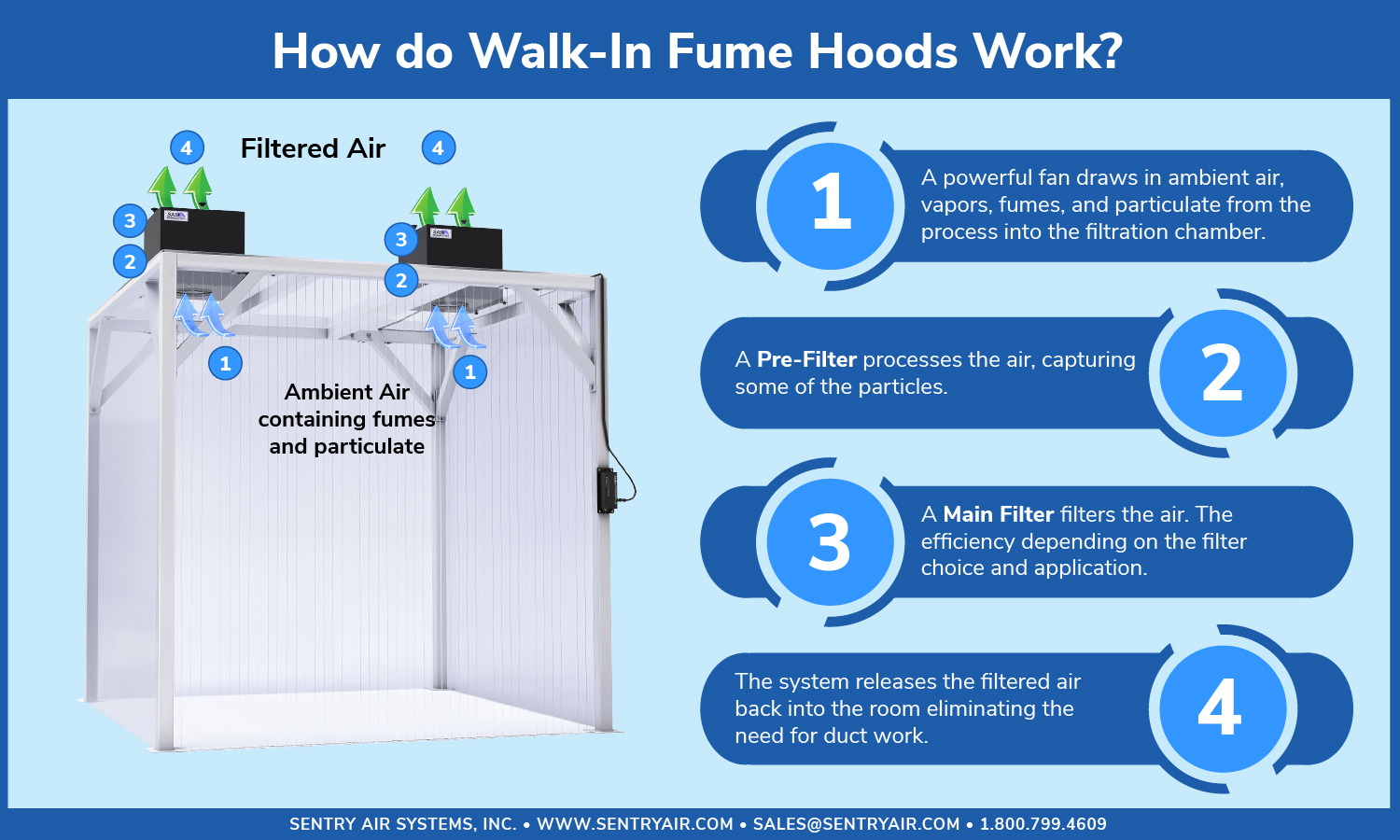

While Sentry Air Walk-in Enclosures have several customizable features, the traditional design includes four structural supports, clear panel curtain walls, and a ceiling panel with mounted ductless air filtration units.The curtained wall doubles as the entrance and exit to the enclosure as well as acting as a barrier surrounding the enclosure. The structural supports maintain the integrity of the enclosure while supporting the weight of the ceiling panel and filtration units. The filtration units utilize powerful fans to create negative pressure that then pulls fume, dust, and vapor from within the enclosure into the units’ filter chamber before releasing cleansed air back into the ambient room.

Benefits of a Walk-in Fume Hood

- Ideal for large equipment use, drums storage, and creating a dust- or grinding-safe environment

- Customizable to most applications

- Available in ducted and filtered style

- Environmentally friendly

- Efficient odor and toxic fume ventilation

- Made in the USA

Fume Hood Safety Considerations

Safe operation of your fume hood is critical to aiding in protecting your staff and anyone around (or in) it. A walk-in fume hood should only be considered for use in labs with low hazard chemicals.

- They should be visually inspected frequently

- Pedestrian traffic in front of the hood should be limited

- If your fume hood is used often, a regular cleaning schedule should be established

Product Video

Material:

3" x 3" Steel Structual Tubing Powder Coated

1/4" Clear Acrylic Sides

Height:

Up to 9 feet

Width & Depth:

Up to 20 feet

Weight:

Steel tubing: 3.29 lbs/ft

Acrylic: 1.44 lbs/sqft

Options:

Floor Mounting, Clear Anti-Static Vinyl Strip Curtains, Floor (HDPE), Multiple Filter Units, Collars for Ductwork

Available Filter Units:

SS-300-MS or SS-400/450-MS

Single or multiple units are available depending on hood size.

Wall mounted units with a connecting hose are also an option.

Available Filter Efficiencies:

HEPA Filter - Up to 99.97% efficient on particles down to 0.3 microns in size.

ASHRAE Filter - Up to 95% efficient on particles down to 0.5 microns in size.

ULPA Filter - Up to 99.9995% efficient on particles down to 0.12 microns in size.

Activated Carbon & Specialty-Blended Filters - Efficiency varies per chemical.

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

U.S. PATENT #8,353,745

Product Video

Material:

1.5" x 1.5" Brushed Aluminum Tubing

1/4" Clear Acrylic Sides

Height:

Up to 6 feet

Width & Depth:

Up to 6 feet

Weight:

Aluminum tubing: .9 lbs/ft

Acrylic: 1.44 lbs/sqft

Options:

Floor Mounting, Clear Anti-Static Vinyl Strip Curtains (only one side), Floor (HDPE), Collars for Ductwor

Available Filter Units:

SS-300-MS or SS-400/450-MS

Single or multiple units are available depending on hood size.

Wall mounted units with a connecting hose are also an option.

Available Filter Efficiencies:

HEPA Filter - Up to 99.97% efficient on particles down to 0.3 microns in size.

ASHRAE Filter - Up to 95% efficient on particles down to 0.5 microns in size.

ULPA Filter - Up to 99.9995% efficient on particles down to 0.12 microns in size.

Activated Carbon & Specialty-Blended Filters - Efficiency varies per chemical.

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

U.S. PATENT #8,353,745

Quick Compare

Heavy-Duty Steel Framed

|

Lighter Aluminum Framed

|

|

|---|---|---|

| Material: |

3" x 3" Steel Structual Tubing Powder Coated 1/4" Clear Acrylic Sides |

1.5" x 1.5" Brushed Aluminum Tubing 1/4" Clear Acrylic Sides |

| Height: | Up to 9 feet | Up to 6 feet |

| Width & Depth: | Up to 20 feet | Up to 6 feet |

| Weight: |

Steel tubing: 3.29 lbs/ft Acrylic: 1.44 lbs/sqft |

Aluminum tubing: .9 lbs/ft Acrylic: 1.44 lbs/sqft |

| Options: | Floor Mounting, Clear Anti-Static Vinyl Strip Curtains, Floor (HDPE), Multiple Filter Units, Collars for Ductwork | Floor Mounting, Clear Anti-Static Vinyl Strip Curtains (only one side), Floor (HDPE), Collars for Ductwork |

Accessories

SS-400-QCPF

Allows easy access to pre-filters

SS-400-RCB

Controls unit operation remotely

SS-300-MAG

Monitors filter saturation

SS-000-HC

Displays hours unit has been in operation

Made in the USA

Made in the USA